Operating a commercial crushing plant in Pakistan involves several steps, each requiring careful planning and adherence to local regulations. Here is a general guide:

Legal and Regulatory Compliance:

- Business Registration: Register your business with the Securities and Exchange Commission of Pakistan (SECP).

- Environmental Clearance: Obtain environmental clearance from the Pakistan Environmental Protection Agency (EPA) to ensure your operation meets environmental standards.

- Local Permits: Secure permits from local authorities, including land use permits and other necessary licenses.

Site Selection and Preparation:

- Location: Choose a location that is suitable for a crushing plant, considering factors such as proximity to raw material sources, market, and transportation facilities.

- Land Acquisition: Acquire or lease land legally, making sure the land is zoned for commercial use.

- Site Preparation: Prepare the site by clearing it, leveling the ground, and setting up necessary infrastructure like access roads and utilities.

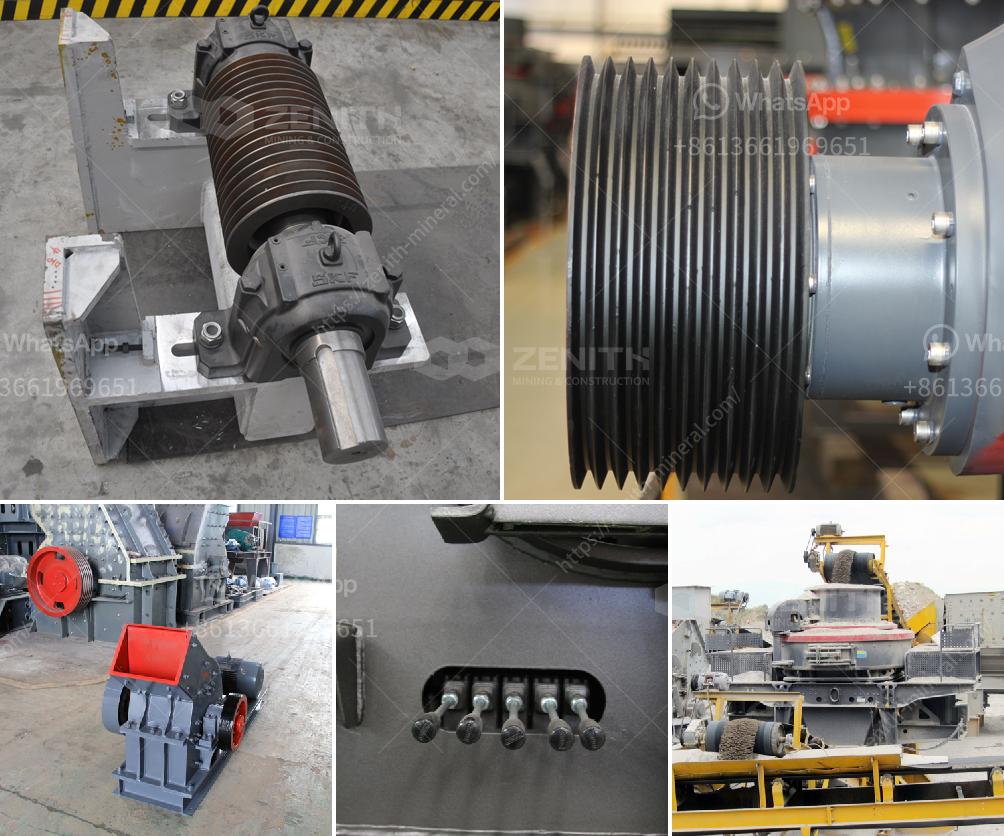

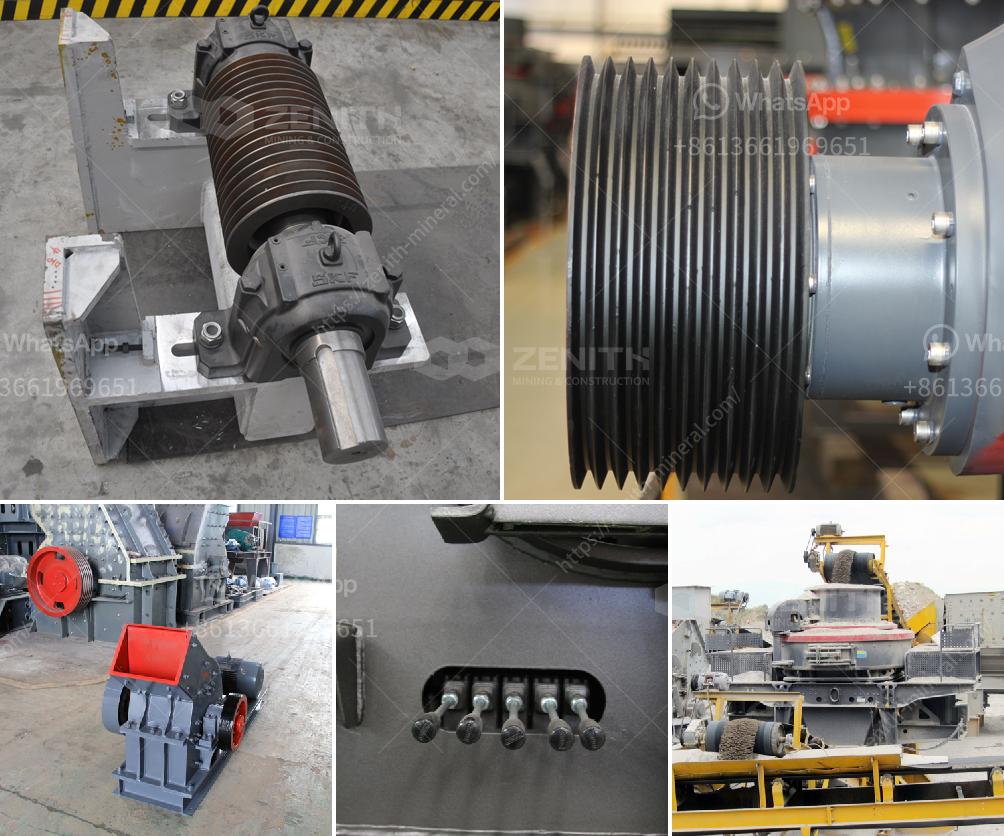

Equipment and Installation:

- Machinery Procurement: Purchase or lease necessary crushing machinery, such as jaw crushers, cone crushers, and vibrating screens. Brands like Metso, Sandvik, and Terex are popular choices.

- Installation: Install the machinery according to the manufacturer's guidelines. Ensure all safety and operational protocols are in place.

Staffing and Training:

- Hiring: Employ qualified personnel, including plant managers, operators, maintenance technicians, and administrative staff.

- Training: Provide comprehensive training to staff on equipment operation, safety procedures, and maintenance practices.

Operations:

- Raw Material Supply: Establish contracts with suppliers to ensure a steady supply of raw materials such as rocks and stones.

- Production Process: Implement a structured production process, including primary crushing, secondary crushing, and screening. Monitor the quality of the output to ensure it meets industry standards.

- Safety Measures: Enforce strict safety measures, including wearing personal protective equipment (PPE) and adhering to safety protocols to prevent accidents.

Quality Control and Maintenance:

- Quality Assurance: Regularly check the quality of the crushed material to meet the required specifications.

- Maintenance Schedule: Develop and adhere to a regular maintenance schedule to minimize downtime and extend the lifespan of the machinery.

Environmental and Social Responsibility:

- Waste Management: Implement proper waste management practices to handle by-products and ensure minimal environmental impact.

- Community Relations: Maintain good relations with the local community by addressing their concerns and contributing to local development.

Financial Management:

- Budgeting: Prepare a detailed budget covering all operational costs, including raw materials, labor, maintenance, and administrative expenses.

- Financial Tracking: Regularly monitor financial performance to ensure profitability and identify areas for cost reduction.

Marketing and Sales:

- Market Analysis: Conduct market research to understand demand and pricing strategies.

- Sales Strategy: Develop a sales strategy, including direct sales, distribution partnerships, and marketing campaigns to attract customers.

By following these steps and staying compliant with local laws and regulations, you can effectively operate a commercial crushing plant in Pakistan.