Designing a marble or stone processing production line involves several crucial steps to ensure efficiency, quality, and safety. Here's a detailed guide:

1. Preliminary Planning and Analysis

- Market Research: Understand market demand, the type of marble or stone that is popular, and potential competitors.

- Budgeting: Determine the budget for machinery, labor, and other operational costs.

- Regulations: Familiarize yourself with local regulations and environmental standards.

2. Choosing the Right Location

- Proximity to Quarries: Select a location close to the source of raw materials to reduce transportation costs.

- Infrastructure: Ensure the location has adequate infrastructure, including water supply, electricity, and transportation links.

3. Designing the Layout

- Material Flow: Design the plant layout to support a smooth and continuous material flow from raw material intake to finished product dispatch.

- Segmentation: Divide the production line into sections such as raw material storage, cutting, grinding, polishing, and finishing.

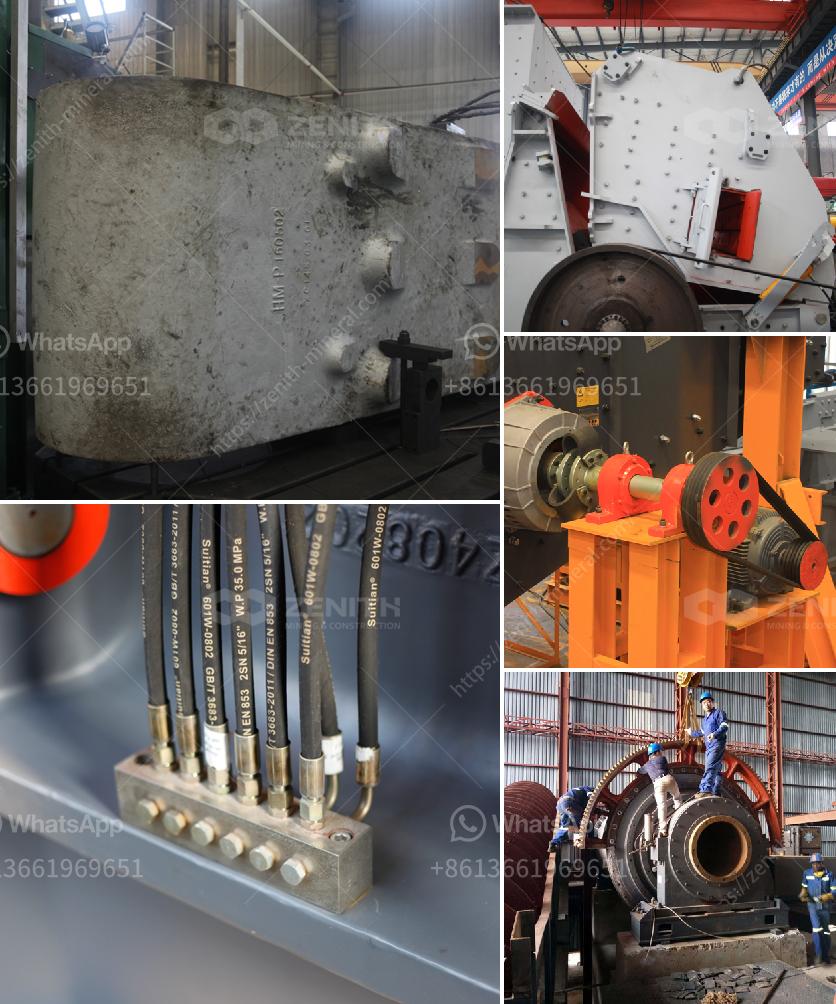

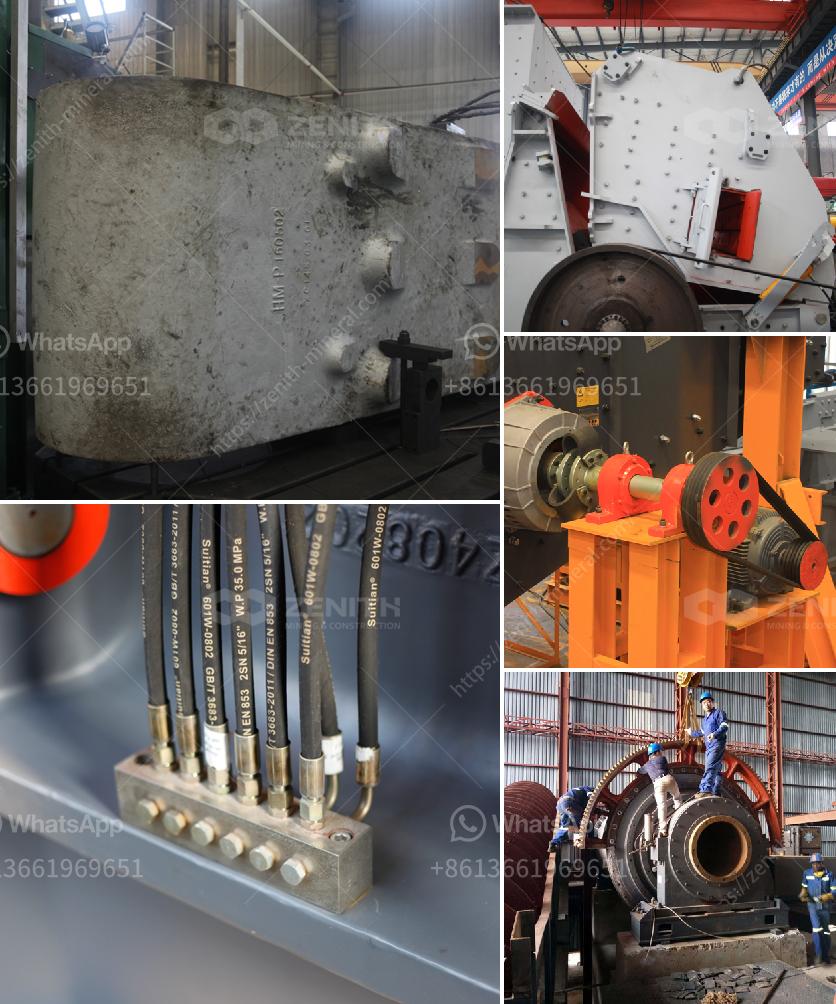

4. Selecting Machinery and Equipment

- Cutting Machines: Choose high-precision saws and cutting machines suitable for marble or stone.

- Polishing Machines: Invest in multiple stages of polishing machines to ensure a high-quality finish.

- CNC Machines: For detailed and custom designs, consider Computer Numerical Control (CNC) machines.

- Conveyor Systems: Implement conveyor belts to facilitate the movement of materials between different sections of the production line.

- Quality Control Equipment: Install inspection machines to detect any flaws or defects in the stones.

5. Automation and Technology Integration

- Software Systems: Use ERP (Enterprise Resource Planning) software for the overall management of operations.

- IoT Integration: Implement sensors and IoT devices for real-time monitoring of machinery and production quality.

- Energy Efficiency: Invest in energy-efficient machinery to reduce operational costs and comply with environmental regulations.

6. Human Resources and Training

- Skilled Workers: Hire experienced professionals for machine operations, quality control, and safety management.

- Training Programs: Develop training programs to enhance the skills of your workforce in handling advanced machinery and maintaining safety standards.

7. Implementing Safety Measures

- Protective Gear: Ensure that all workers have the necessary protective gear.

- Safety Protocols: Establish and enforce safety protocols for machinery operation and material handling.

8. Waste Management and Recycling

- Waste Disposal: Develop a comprehensive waste management plan for marble or stone scraps.

- Recycling: Explore opportunities to recycle stone waste into by-products like aggregates or reconstituted stone.

9. Quality Control and Assurance

- Standards Compliance: Ensure that the production processes comply with national and international quality standards.

- Regular Inspection: Implement regular inspection routines to maintain the quality of the product.

10. Continuous Improvement

- Feedback Loop: Establish a feedback mechanism to continuously assess and improve the production process.

- Innovation: Stay updated with the latest technology and market trends to keep the production line competitive.

By following these steps, you can design a marble or stone processing production line that is efficient, cost-effective, and capable of producing high-quality products.