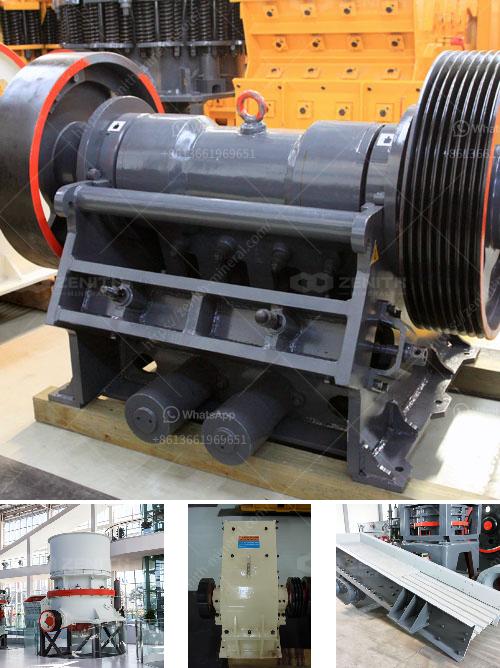

An aggregate crusher is a machine designed to grind or pulverize various types of rock into small, relatively uniform pieces. Aggregate crushers are used in mining, quarrying, and recycling operations. Several types of crushers can perform this task, including jaw crushers, cone crushers, impact crushers, and gyratory crushers.

Jaw Crushers:

Cone Crushers:

Impact Crushers:

Gyratory Crushers:

Aggregate crushers play a crucial role in the construction and mining industries. They provide the necessary materials for building infrastructure, such as roads, bridges, and buildings. The quality and size of the aggregate produced by these crushers directly impact the strength and durability of the construction projects.

Regular maintenance of aggregate crushers is essential to ensure their longevity and efficient operation. This includes checking and replacing wear parts, lubricating moving parts, and ensuring that the machine is operating within its designed parameters. Safety is also a critical aspect, as these machines can be hazardous. Proper training, safety protocols, and protective equipment are necessary to prevent accidents.

In summary, an aggregate crusher is a vital piece of equipment in the construction and mining industries, designed to break down large rocks into smaller, more manageable pieces for use in various applications. Different types of crushers are available, each with its specific advantages and applications, making them indispensable in producing high-quality aggregate materials.