Building a small crusher production line involves several steps ranging from planning and design to purchasing equipment and installation. Here’s a basic guide to help you get started:

1. Planning and Design

- Determine Requirements: Assess the materials you need to crush (e.g., stone, concrete, metal) and the expected output capacity.

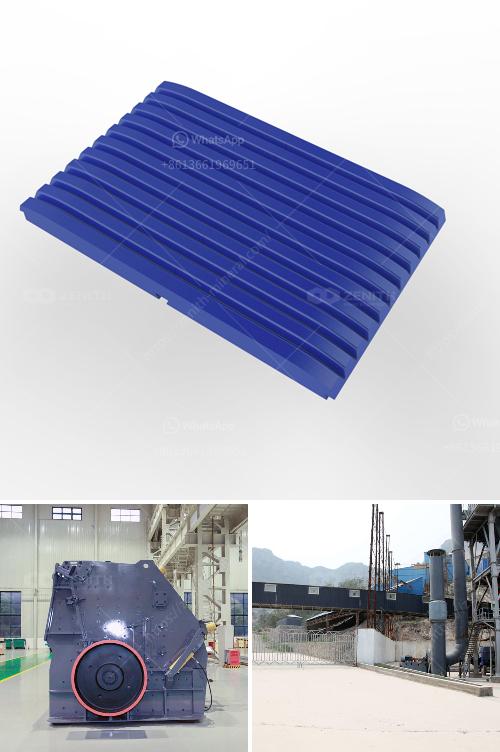

- Site Selection: Choose a suitable location with enough space for equipment, stockpiles, and ease of access.

- Regulatory Compliance: Check local regulations for environmental and safety standards.

2. Equipment Selection

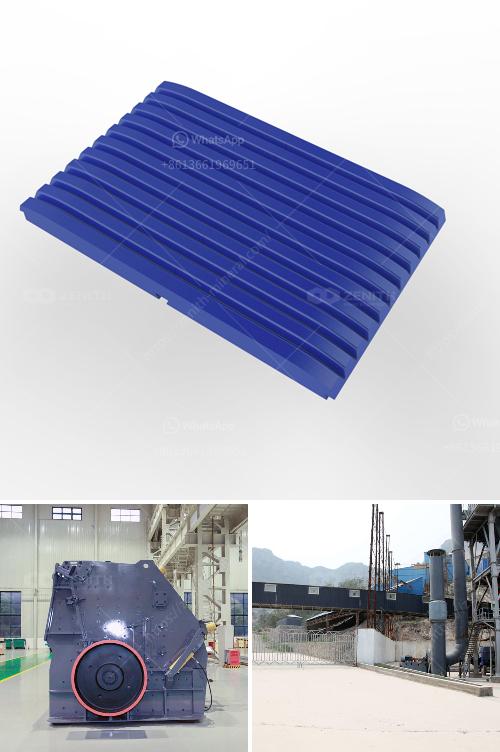

- Primary Crusher: This could be a jaw crusher or impact crusher, depending on the material and size.

- Secondary Crusher: Depending on the final product requirements, you might need a cone crusher or other type of secondary crushing apparatus.

- Conveyors: To transport material between stages.

- Screening Equipment: To separate different sizes of crushed material.

- Dust Collection System: To minimize dust and ensure environmental compliance.

- Control Panel: For easy operation and monitoring.

3. Purchase and Delivery

- Research Suppliers: Look for reputable suppliers with good reviews and customer service.

- Request Quotes: Get detailed pricing and specifications from multiple suppliers.

- Place Orders: Once comparisons are made, order the required equipment.

4. Installation

- Foundation Work: Prepare the site, including concrete foundations for heavy equipment.

- Set Up Equipment: Position and secure crushers, conveyors, and screens as per the design layout.

- Electrification: Install electrical systems and control panels, ensuring everything is up to code.

5. Testing and Adjustments

- Inspection: Check the installation thoroughly before starting up.

- Initial Run: Start the production line and observe for any issues or adjustments needed.

- Calibration: Fine-tune settings for optimal performance.

6. Maintenance and Operations

- Training: Make sure your staff is adequately trained on operation and safety procedures.

- Regular Maintenance: Establish a routine maintenance schedule to ensure longevity and reliability of the equipment.

- Spare Parts: Keep essential spare parts on hand to minimize downtime.

7. Scalability and Optimization

- Monitor and Review: Continuously monitor the production line's performance and look for areas of improvement.

- Upgrade: As demand grows, consider upgrading or adding more equipment to increase capacity and efficiency.

Would you like more detailed information on any specific part of the process?