The iron ore thickening process is a method used to increase the concentration of iron ore particles within a given volume by removing excess water. This process typically involves several steps:

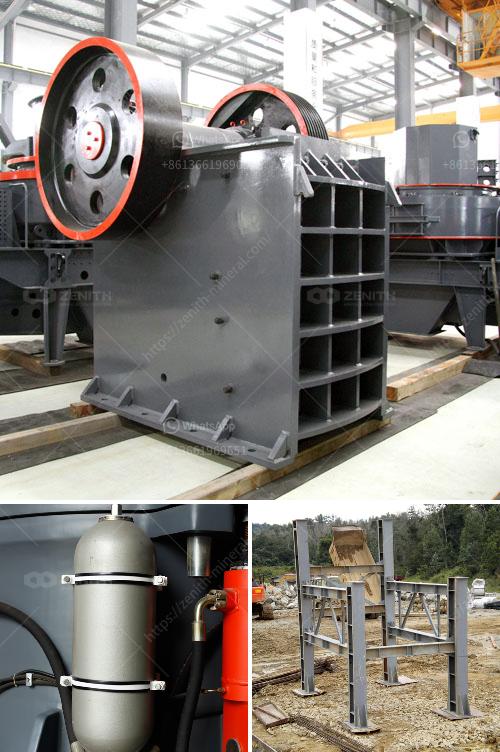

Crushing and Grinding: The iron ore is first crushed and ground to liberate the iron particles from the surrounding rock.

Concentration: Various concentration methods such as gravity separation, magnetic separation, or flotation are used to increase the iron content while removing impurities.

Thickening: The slurry (mixture of water and iron ore particles) is then fed into a thickener or settling tank. Here, flocculants may be added to help the iron ore particles clump together and settle to the bottom more quickly. The clear water overflows and is typically recycled back into the process, while the thickened sludge or concentrate is drawn off from the bottom.

Dewatering: The thickened iron ore concentrate may require additional dewatering using filters or centrifuges to reduce the moisture content to the desired level.

Tailings Management: The water and waste materials separated from the ore are managed according to environmental regulations.

This process is crucial for improving the efficiency of subsequent processing steps and for minimizing transportation and storage costs by reducing the volume of material to be handled.