The production of stone aggregates involves several key steps. Here’s a brief overview of the process:

-

Extraction:

- Quarrying: Aggregates are typically sourced from quarries. Here, large rocks are extracted using explosives or heavy machinery like bulldozers and excavators.

-

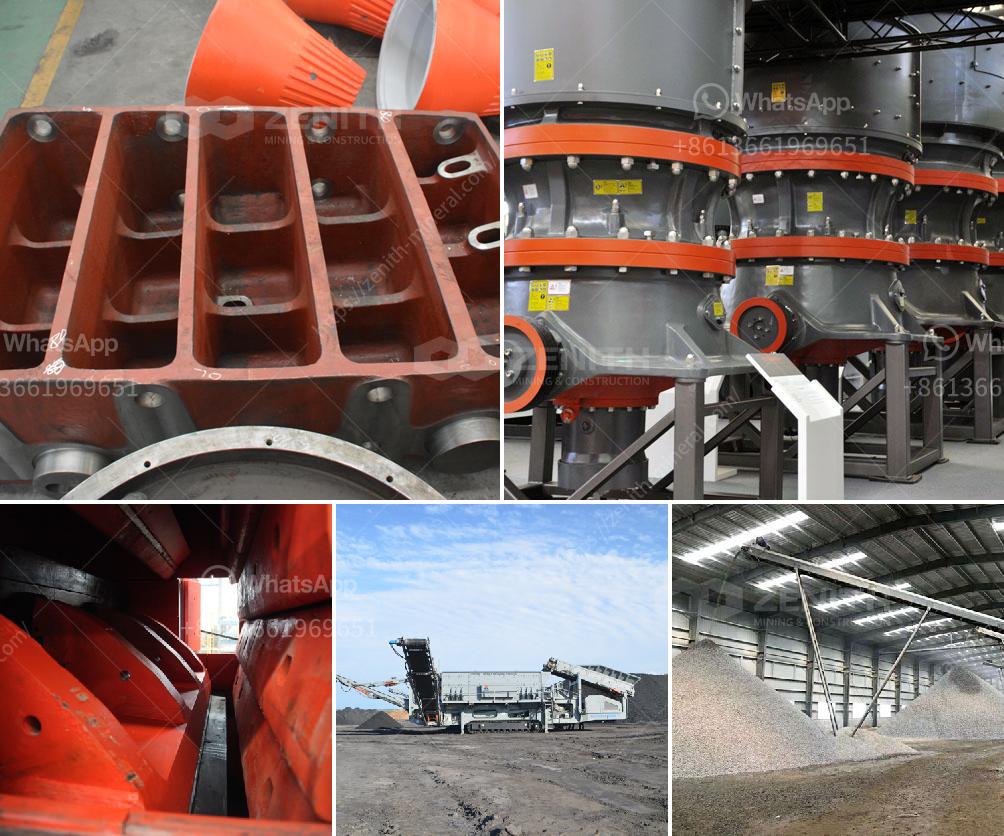

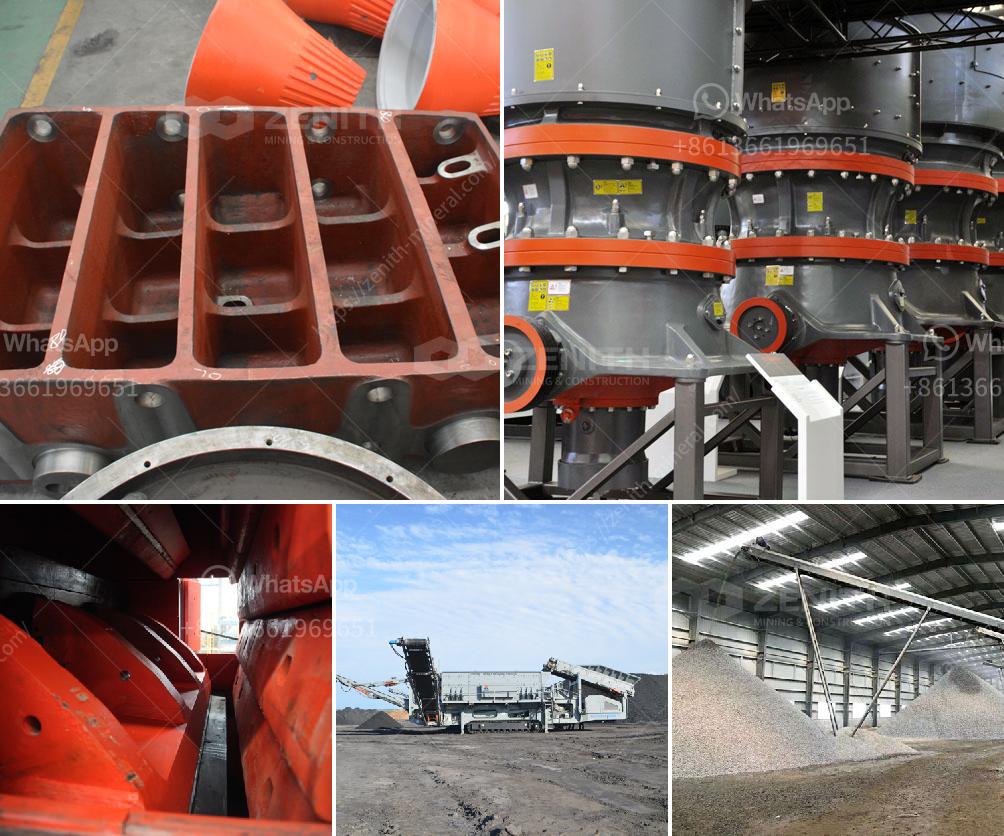

Crushing:

- Primary Crushing: The large rocks extracted from the quarry are fed into a primary crusher, which breaks them down into smaller, manageable pieces.

- Secondary Crushing: The smaller pieces are then transported to secondary crushers that reduce the size further.

-

Screening:

- After crushing, the materials are screened to separate different sizes. Screens filter the aggregates to produce uniform particle sizes and remove any unwanted material or debris.

-

Washing:

- In some cases, particularly where the aggregates are intended for concrete production or other specific applications, they might be washed to remove any fine particles such as clay, silt, or dust.

-

Grading:

- Aggregates are then graded based on size and type, often using a series of sieves or screens. This ensures the product meets specific standards and criteria for different construction purposes.

-

Storage:

- The final, graded aggregates are stored in bins or stockpiles, ready to be transported to construction sites or further processing.

-

Quality Control:

- Throughout the production process, quality control measures are undertaken. Samples are regularly tested to ensure the aggregates meet industry standards and specifications.

-

Transport:

- Finally, the aggregates are loaded into trucks, railcars, or barges and transported to their end destinations, such as construction sites or concrete plants.

Each of these steps is crucial to ensuring that the stone aggregates produced are of high quality and fit for use in various construction applications.