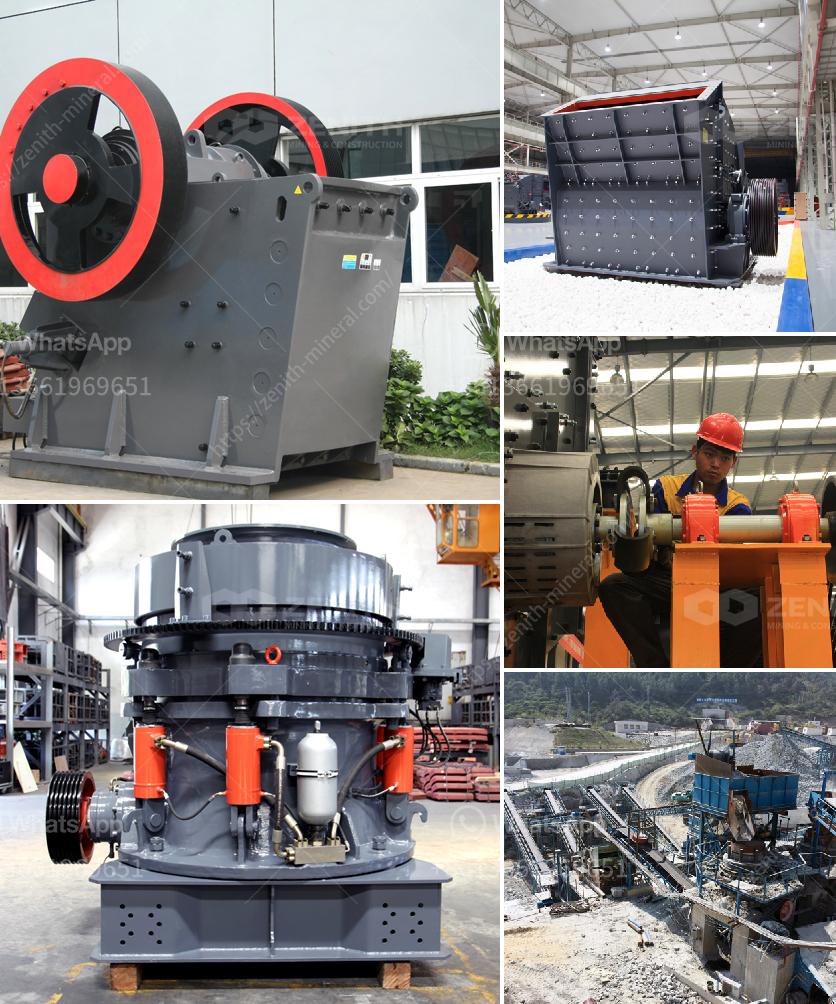

A jaw crusher works by using compressive force to break down materials into smaller, more manageable pieces. Here is a simplified explanation of its operation:

Feeding the Crusher: Material is fed into the top of the jaw crusher, usually by a vibrating grizzly feeder that manages the flow and filters out smaller particles (fines).

Crushing Mechanism: The jaw crusher has two jaws: one static (stationary) and one that moves (oscillates). The moving jaw is pivoted at the top, creating a motion that impacts the materials in a wedging and squeezing manner.

Crushing Process:

Discharge: Crushed material is discharged from the bottom of the jaw crusher once it reaches the desired size. The size of the output can be adjusted by altering the gap between the jaws.

Cycle: This process repeats as new material is continuously fed into the top of the crusher, and crushed material is discharged out of the bottom.

This mechanical simplicity, combined with robust construction, makes jaw crushers ideal for primary crushing of various hard and abrasive materials in many different industries.