Stone crusher machines come in various types, each tailored for specific tasks and materials. Here are the main types of stone crusher machines:

-

Jaw Crusher:

- Best for primary crushing.

- Works by using compressive force, with two jaw plates—one fixed and one movable.

- Suitable for hard and abrasive materials.

-

Impact Crusher:

- Used for secondary crushing.

- Relies on impact rather than pressure to crush materials.

- Ideal for softer, less abrasive materials like limestone.

-

Cone Crusher:

- Also used for secondary or tertiary crushing.

- Works by squeezing the material between a gyrating cone and a fixed outer wall.

- Suitable for medium to hard materials.

-

Gyratory Crusher:

- Similar to jaw crushers but with a gyrating spindle in the center.

- Used for primary or secondary crushing of large quantities of hard materials.

-

Hammer Crusher:

- Utilizes hammers to crush the material.

- Suitable for softer stones, often used in smaller industries for crushing coal, salt, chalk, gypsum, and limestone.

-

Roll Crusher:

- Consists of two or more rotating cylinders, or rolls.

- Used for producing finer particles usually.

- Suitable for soft to medium-hard materials.

-

VSI (Vertical Shaft Impact) Crusher:

- Specialized for shaping and fine crushing.

- Uses high-speed rotors with wear-resistant tips to "throw" the material against crushing chambers.

- Efficient for sand making and producing aggregate particles.

-

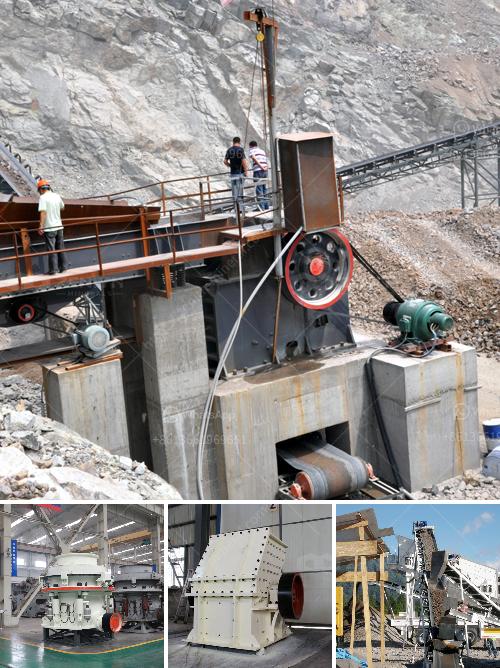

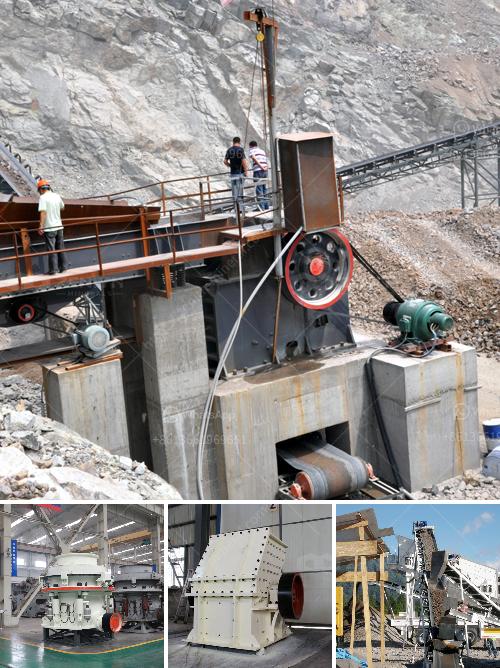

Mobile Crushers:

- Portable versions of the other crushers, providing flexibility and ease of transport.

- Often used on construction sites or in difficult-to-access locations.

-

Compound Crusher:

- Combines features of multiple crushers for versatility.

- Suitable for various applications where requirements for particle size, shape, or type of material differ.

Each type of crusher has its own strengths and appropriate applications, depending on the desired output and characteristics of the material to be processed.