A grinding mill for limestone in Tanzania operates using similar principles as those found in other regions, though local factors such as the availability of resources, infrastructure, and energy can impact its operation. Here's a general overview of how a grinding mill for limestone typically works:

-

Extraction and Preparation:

- Quarrying: Limestone is extracted from quarries or mines. In Tanzania, this might involve basic mining operations where limestone is abundant.

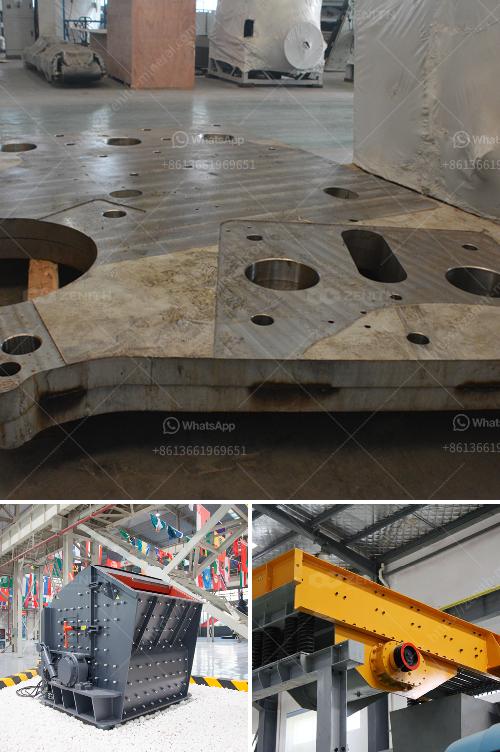

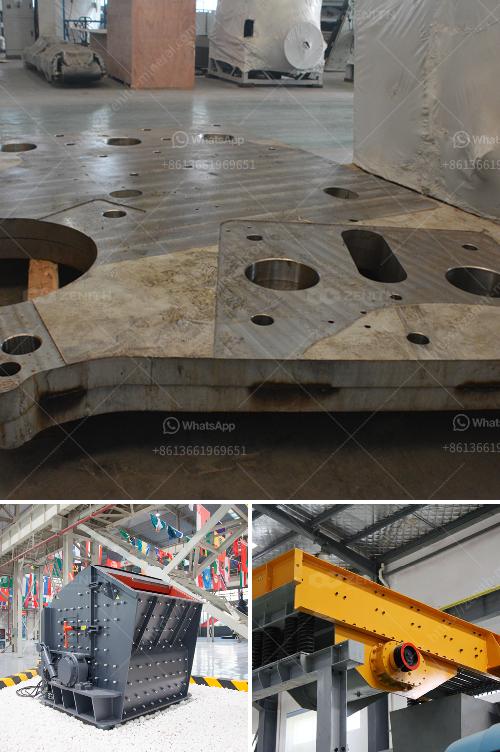

- Crushing: The extracted limestone is initially crushed to smaller pieces using crushers. This facilitates easier handling and grinding down the line.

-

Grinding Process:

- Feeding: Crushed limestone is evenly fed into the grinding mill. This can be done using a vibrating feeder or conveyors.

- Grinding Mechanism: The grinding mill uses mechanical forces to pulverize the limestone into a fine powder. The type of mill—whether a ball mill, hammer mill, or vertical roller mill—affects this process:

- Ball Mill: It uses steel balls that roll around as the mill rotates, crushing the limestone under its weight.

- Vertical Roller Mill: It uses large rollers that crush the limestone against a rotating slab.

- Hammer Mill: Utilizes heavy hammers to break down materials.

-

Classification and Collection:

- Separators: After grinding, the ground limestone is passed through air separators or classifiers to separate fine particles from coarser ones.

- Collection: Finer particles are collected as finished product, while coarser particles may be returned for further grinding.

-

Dust Collection and Efficiency:

- Cyclones and Dust Collectors: These are often used to reduce dust emissions and improve air quality. They capture airborne particles during the grinding and transporting processes.

-

Output Uses:

- Building Materials: Ground limestone is often used in cement production in Tanzania.

- Agricultural Uses: It can improve soil pH.

- Industrial Applications: It is used in various industrial processes or as a filler material.

Local Considerations in Tanzania:

- Power Supply: Mills typically require substantial power. In Tanzania, reliance may be on grid electricity, generators, or renewable sources.

- Water Supply: Some grinding operations use water to reduce dust or heat. Water supply considerations are crucial, especially in less developed areas.

- Logistics: The transportation of raw limestone to mills and finished products to consumers can significantly impact operational efficiency.

Overall, the grinding mill must be suitably equipped and operated to meet the demands of the local market in Tanzania with adjustments possibly needed for local conditions and resources.