Designing a hopper feeder involves several steps to ensure efficient and reliable material handling. Here’s a guide to help you through the process:

1. Define the Requirements

- Material Characteristics: Understand the physical properties of the material to be fed (e.g., particle size, bulk density, moisture content).

- Flow Rate: Determine the required feed rate to match the process needs.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and potential for corrosion or wear.

2. Choose the Hopper Shape

- Cone Hoppers: Suitable for free-flowing materials.

- Wedge Hoppers: Better for materials prone to bridging (where the material forms a bridge and stops flowing).

- Transition Hoppers: Combine attributes of conical and wedge designs for complex applications.

3. Select the Hopper Volume

- Holding Capacity: Ensure the hopper holds a sufficient amount of material to minimize the frequency of refilling.

- Material Reserve: Consider a buffer volume to prevent process interruptions.

4. Flow Assistance Devices

- Vibrators: Help in preventing bridging and ensuring steady material flow.

- Aerators: Useful for fine or cohesive powders.

- Mass Flow or Funnel Flow: Decide whether mass flow (where all material moves concurrently) or funnel flow (central core moves) is ideal depending on material properties.

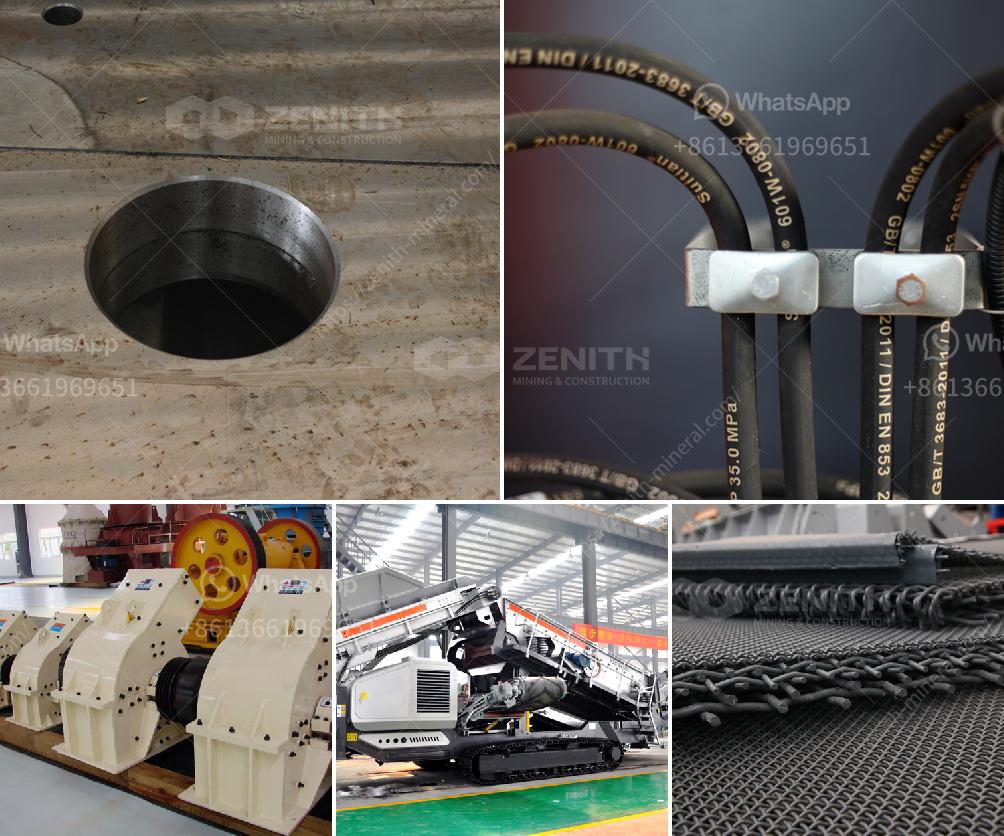

5. Feeder Selection

- Gravimetric Feeders: Measure and control the mass flow rate, suitable for precision applications.

- Volumetric Feeders: Control the volume flow rate, suitable for less critical applications.

- Belt Feeders: Good for large, bulky materials.

- Screw Feeders: Versatile and can handle various materials including powders and granules.

- Vibratory Feeders: Suitable for small and medium-sized particles.

6. Design Mechanics

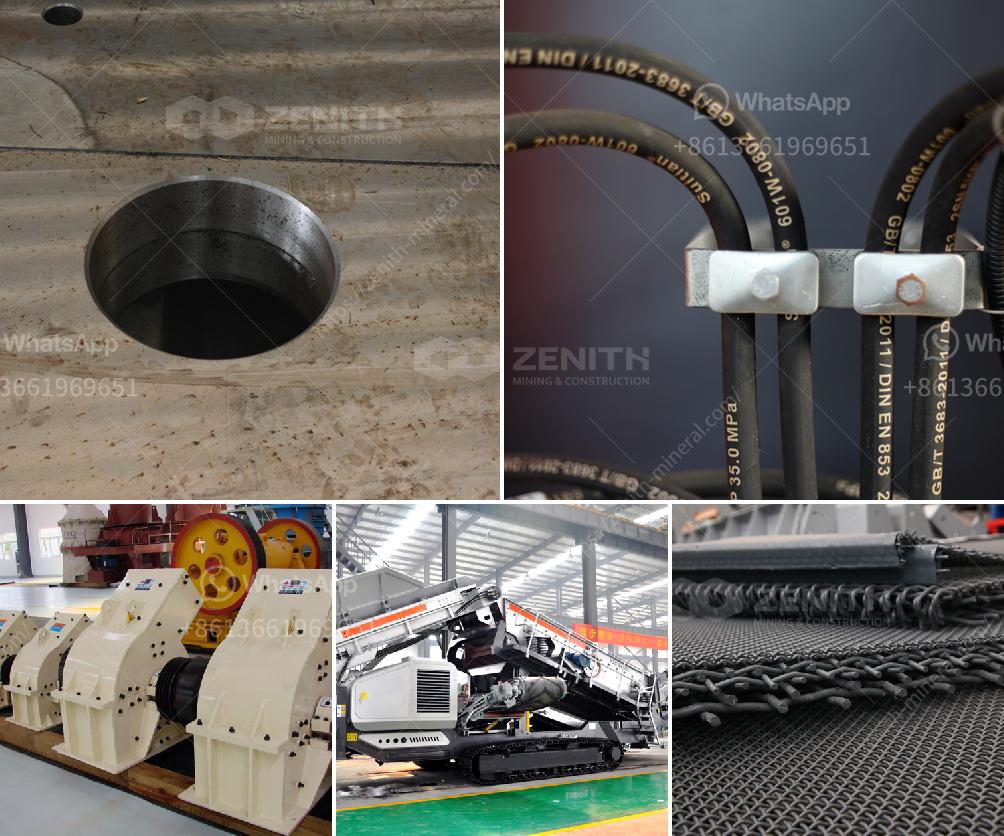

- Discharge Opening: Size the opening to ensure a consistent flow rate without clogging.

- Incline Angle: Design the hopper walls at an angle steep enough to prevent material from sticking, typically above the angle of repose of the material.

- Material Flow Analysis: Use software to model and predict material behavior within the hopper.

7. Safety and Maintenance

- Access Points: Design access for routine maintenance and inspection.

- Safety Gates/Valves: Integrate shut-off mechanisms to block material flow during maintenance or emergencies.

- Wear Protection: Use liners or coatings in high-wear areas to prolong the life of the hopper feeder.

8. Integration with Control Systems

- Sensors: Install sensors to monitor hopper levels and flow rates.

- Control Units: Use programmable logic controllers (PLCs) to automate and optimize feeding processes.

9. Prototyping and Testing

- Prototype Development: Build a small-scale model to test the design under real-world conditions.

- Performance Assessment: Evaluate the prototype for feed rate accuracy, consistency, and material handling issues.

10. Final Design Adjustments

- Iterate: Refine the design based on prototype testing results.

- Optimize: Make necessary adjustments to the dimensions, angles, and components to achieve the desired performance.

By following these steps, you can design a hopper feeder tailored to your specific material handling needs while ensuring efficiency, reliability, and safety.