To pulverize limestone using a crusher, follow these steps:

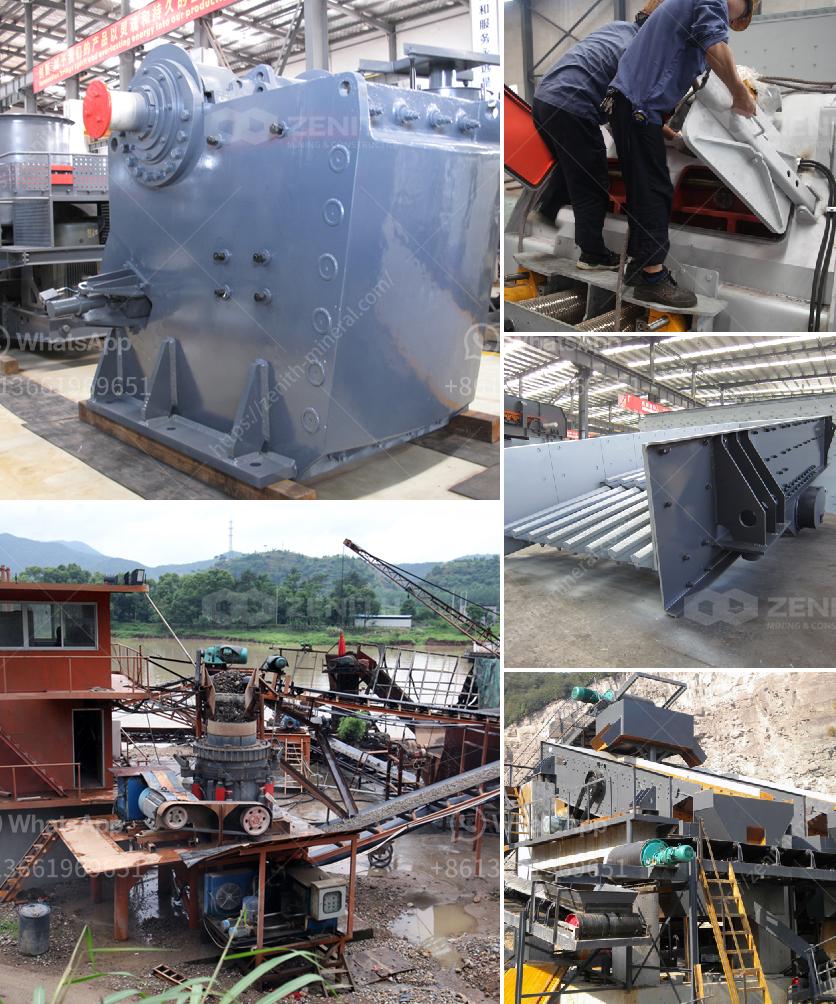

Selection of Equipment: Choose appropriate crushing equipment, such as jaw crushers, hammer mills, or impact crushers, depending on the required final particle size and production capacity.

Initial Crushing: Feed the limestone into the primary crusher to break it down into smaller chunks. A jaw crusher is typically used for this stage to reduce large rocks to manageable sizes.

Secondary Crushing: Use a secondary crusher like an impact crusher or a cone crusher to further reduce the size of the limestone particles. This stage ensures finer material for pulverized output.

Screening: After secondary crushing, pass the material through a vibrating screen to separate finer particles from coarser ones. The desired size particles move forward to the pulverization stage.

Pulverization: Feed the screened limestone into a pulverizer, such as a hammer mill, ball mill, or roller mill, to grind it into a fine powder. Adjust the settings based on the required fineness.

Collection: Collect the pulverized limestone using appropriate methods like bag houses, cyclones, or directly into a storage container for further use.

Quality Control: Ensure the final product meets the desired specifications by conducting tests like sieving, particle size analysis, or chemical composition checks.

Safety and Maintenance: Follow safety protocols at all stages and maintain equipment regularly to ensure efficient and safe operation.

By following these steps, you can effectively pulverize limestone using a crusher for various industrial applications.