Installing a limestone sand washing machine involves several steps. Here’s a comprehensive guide to help you through the process:

1. Pre-Installation Preparation:

- Site Selection: Choose a proper location ensuring it has a solid foundation and proper drainage.

- Utilities: Ensure the availability of electricity, water supply, and any other necessary utilities.

- Tools and Equipment: Gather all required tools such as wrenches, screwdrivers, pliers, and safety gear.

- Manual: Keep the installation manual provided by the manufacturer handy.

2. Foundation and Base Preparation:

- Concrete Base: If required, construct a concrete base to support the machine. Ensure it’s level and stable.

- Anchors: Install any recommended anchor bolts or mounting pads.

3. Machine Positioning:

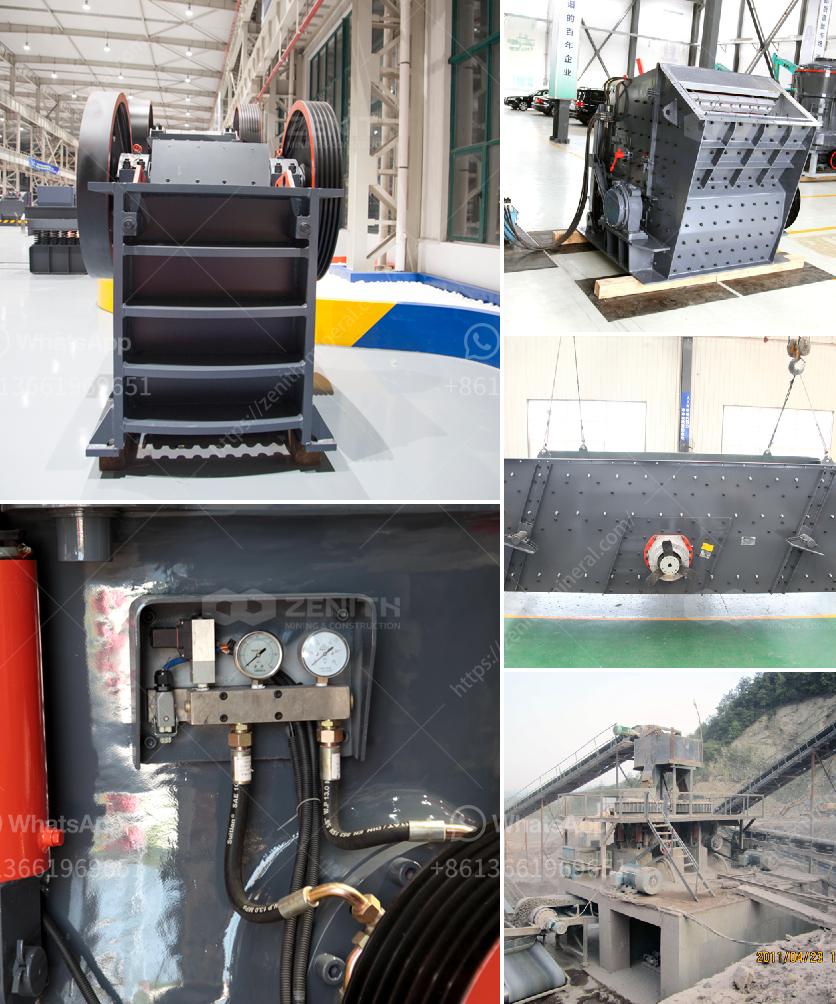

- Unpacking: Carefully unpack the machine and inspect it for any damage.

- Positioning: Place the machine on the prepared base. Use a spirit level to ensure it is level.

- Alignment: Properly align the machine with other equipment in the production line if applicable.

4. Mechanical Installation:

- Fixation: Secure the machine to the base using bolts and nuts as per the manufacturer’s instructions.

- Check Components: Ensure that all parts such as screens, conveyors, and washing components are correctly installed.

5. Electrical Installation:

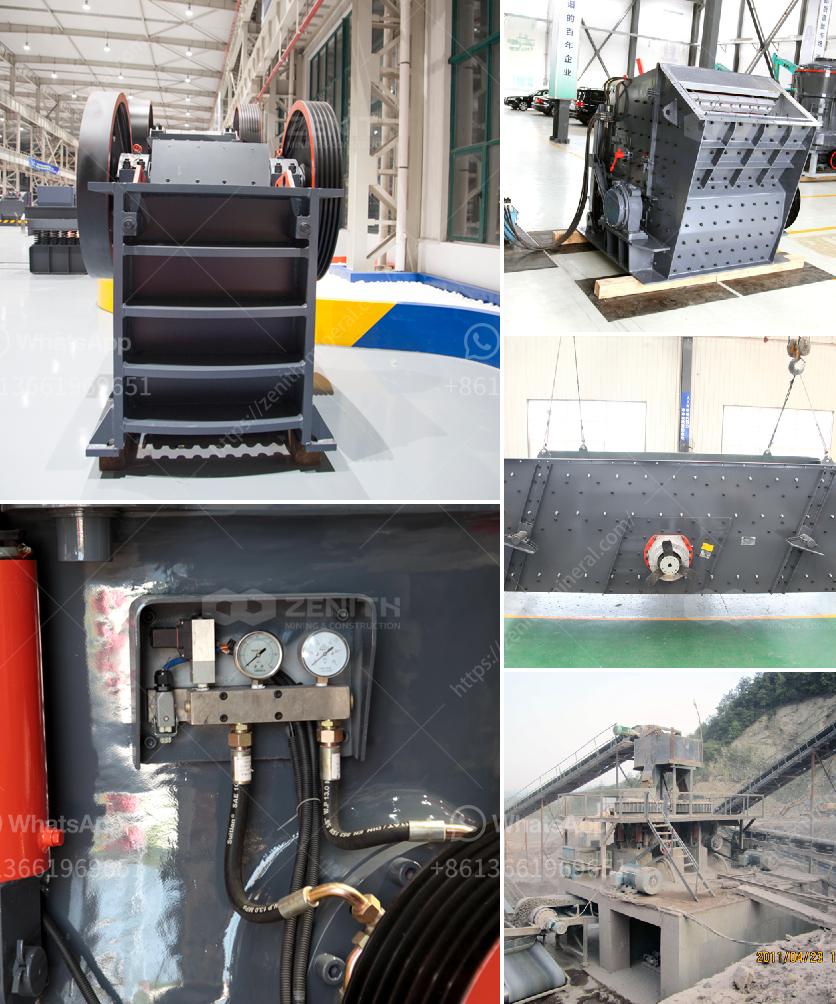

- Power Connection: Connect the machine to the power supply according to the wiring diagram provided. Ensure all connections are secure and comply with safety standards.

- Control Panel: Install the control panel at an accessible location and connect it to the machine as per the manual.

6. Water Supply:

- Piping: Connect the water supply to the machine. Use appropriate piping and secure connections to avoid leaks.

- Valves: Install shut-off valves on the water supply lines for maintenance purposes.

7. Testing and Calibration:

- Dry Run: Perform a dry run of the machine without any load to check for any mechanical issues or unusual noises.

- Water Test: Turn on the water supply and run the machine to ensure proper washing action and that there are no leaks.

- Adjustments: Make necessary adjustments to the settings and aligns as per the desired output and specifications.

8. Training and Safety:

- User Training: Ensure operators are trained on the proper use and maintenance of the machine.

- Safety Checks: Verify all safety mechanisms are functional and the area around the machine is free of hazards.

9. Regular Maintenance:

- Establish a schedule for regular maintenance checks, cleaning, and servicing to ensure the long-term efficiency of the machine.

Final Notes:

Always refer to the specific installation instructions and safety guidelines provided by the machine’s manufacturer. Each model might have unique features and requirements. If you're not confident in performing the installation, consider hiring a professional technician.