Designing a sand washing classifier involves several key steps and considerations to ensure efficiency and effectiveness. Here’s a general guide to help you in the design process:

1. Understand the Purpose and Scope

- Clearly define the objectives: separating sand particles by size and washing to remove impurities.

- Determine the expected input and output, including volume and quality of sand.

2. Material Analysis

- Sand Characteristics: Know the grain size distribution, silt content, and clay content.

- Impurities: Identify the types of impurities such as organic matter, silt, clay, or salts.

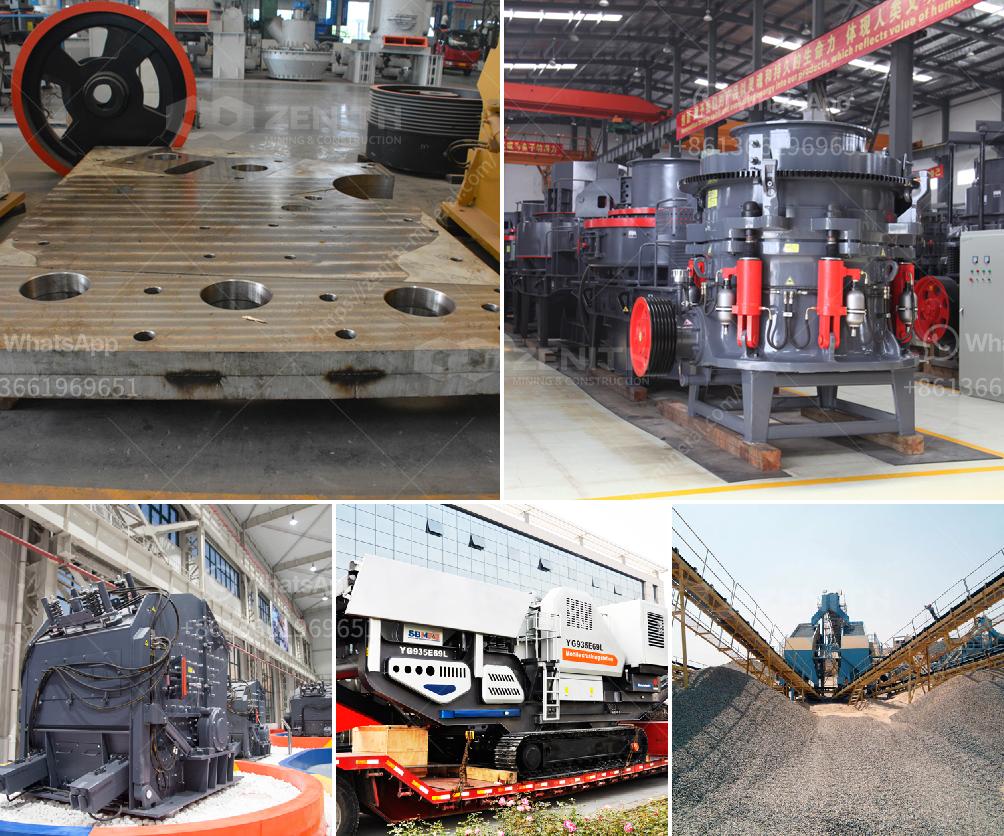

3. Select the Type of Classifier

- Spiral Classifier: Commonly used for sorting fine sand, with a screw mechanism to push sand.

- Hydrocyclone: Uses centrifugal force to separate fine sand.

- Bucket Wheel Classifier: Often preferred for coarser sand, with a rotating wheel that scoops sand.

4. Design Considerations

- Capacity: Determine the processing capacity needed.

- Water Source and Flow Rate: Ensure an adequate and controllable water supply.

- Sand Handling Characteristics: Consider the shape, angle of repose, and flowability of sand.

5. Components and Layout

- Inlet and Feeding Mechanism: Design an efficient inlet to distribute sand evenly.

- Washing Section: Incorporate spray bars, washing troughs, or similar mechanisms to ensure thorough washing.

- Separation Mechanism: Based on your chosen classifier type, design the necessary separators (screw, cyclone, or bucket).

- Discharge Section: Design the outlet for clean sand and another for waste discharge.

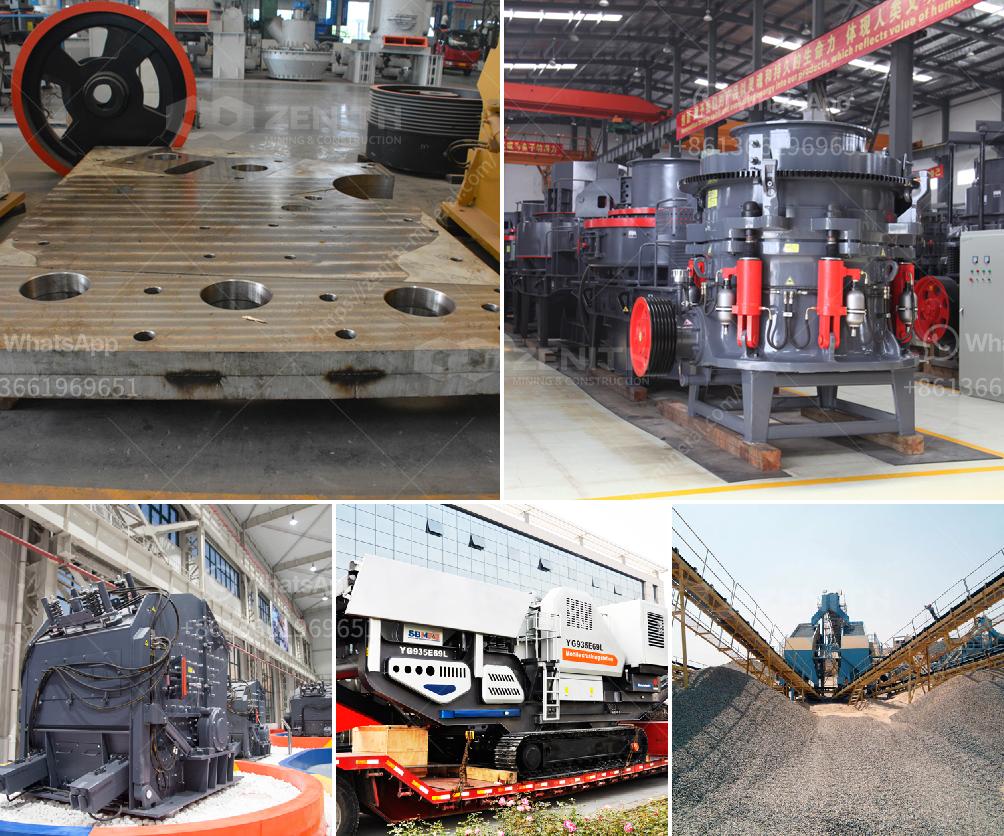

6. Structural and Material Considerations

- Corrosion Resistance: Use materials resistant to abrasion and corrosion (e.g., rubber-lined steel, stainless steel).

- Maintenance Accessibility: Design for easy access to parts that require regular maintenance.

- Structural Integrity: Ensure the framework can withstand operating loads and environmental conditions.

7. Automation and Control

- Implement automated controls for water flow, classifier speed, and monitoring of sand quality.

- Add sensors and feedback systems for real-time adjustments and consistency.

8. Environmental and Safety Concerns

- Plan for waste water treatment or reuse.

- Implement dust control measures.

- Ensure compliance with local and international safety standards.

9. Testing and Prototyping

- Construct a prototype or pilot plant to test the design.

- Perform thorough testing under various conditions and make necessary adjustments.

10. Implementation and Optimization

- After successful testing, implement the full-scale classifier.

- Continuously monitor the performance and make adjustments as needed to optimize efficiency.

Conclusion

Designing an efficient sand washing classifier requires careful planning, material consideration, and systematic testing. By following the steps above, you can create a system that effectively separates and washes sand while ensuring operational efficiency and durability.