Increasing the production capacity of a stone grinding machine involves several strategies and considerations. Here are some detailed steps and methods to achieve this:

1. Upgrade the Machine Components

- Motor Power: Upgrading to a more powerful motor can increase the grinding speed and efficiency.

- Grinding Wheels: Use high-quality, durable grinding wheels that can handle higher loads and last longer.

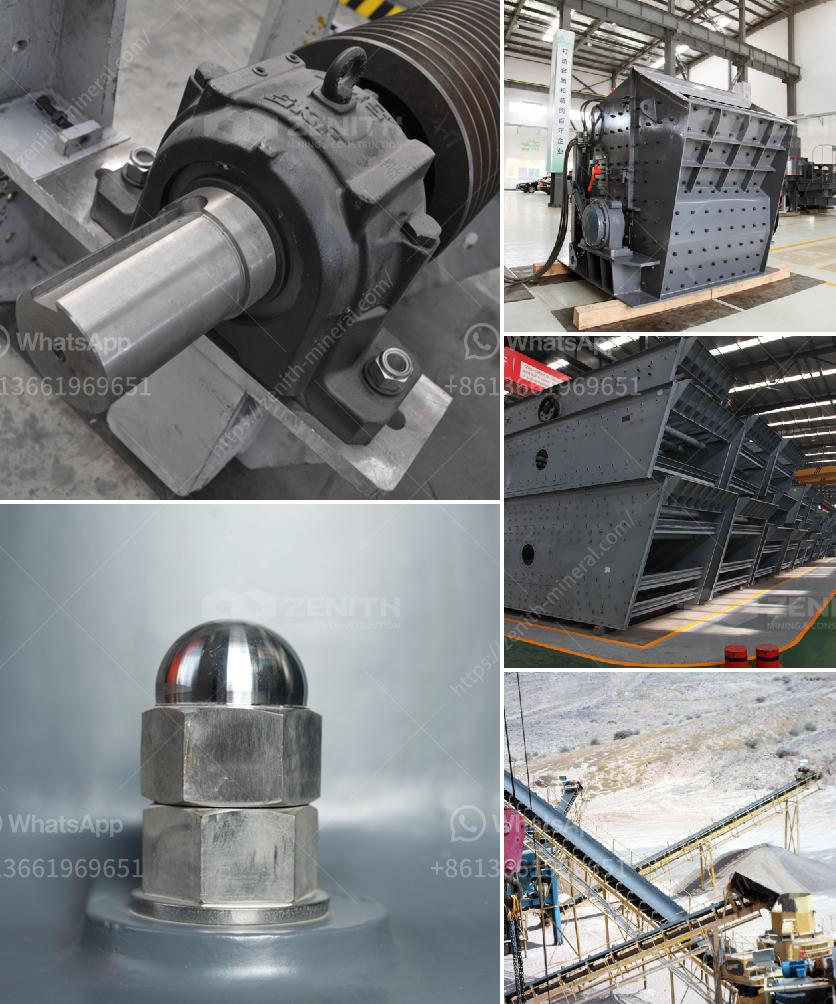

- Bearings and Spindles: Ensure that the bearings and spindles are of high quality to reduce friction and wear, which can improve the machine's overall performance.

2. Optimize the Grinding Process

- Feed Rate: Adjust the feed rate to ensure that the material is being processed at an optimal speed. Too fast can cause overheating and wear, while too slow can reduce productivity.

- Coolant Use: Proper use of coolants can reduce heat and friction, allowing the machine to run faster and more efficiently.

- Grinding Techniques: Implement advanced grinding techniques such as creep-feed grinding, which can remove more material in a single pass.

3. Regular Maintenance

- Scheduled Maintenance: Regularly scheduled maintenance can prevent unexpected breakdowns and ensure that the machine is always running at peak efficiency.

- Lubrication: Keep all moving parts well-lubricated to reduce friction and wear.

- Inspection: Regularly inspect the machine for any signs of wear or damage and replace parts as needed.

4. Automation and Control Systems

- CNC Integration: Integrate Computer Numerical Control (CNC) systems to automate the grinding process, which can increase precision and reduce manual labor.

- Sensors and Monitoring: Use sensors to monitor the machine's performance in real-time and make adjustments as needed to optimize production.

5. Training and Skill Development

- Operator Training: Ensure that all operators are well-trained in the use of the machine and understand the best practices for maximizing productivity.

- Skill Development: Invest in ongoing training and development to keep operators up-to-date with the latest techniques and technologies.

6. Material Handling and Preparation

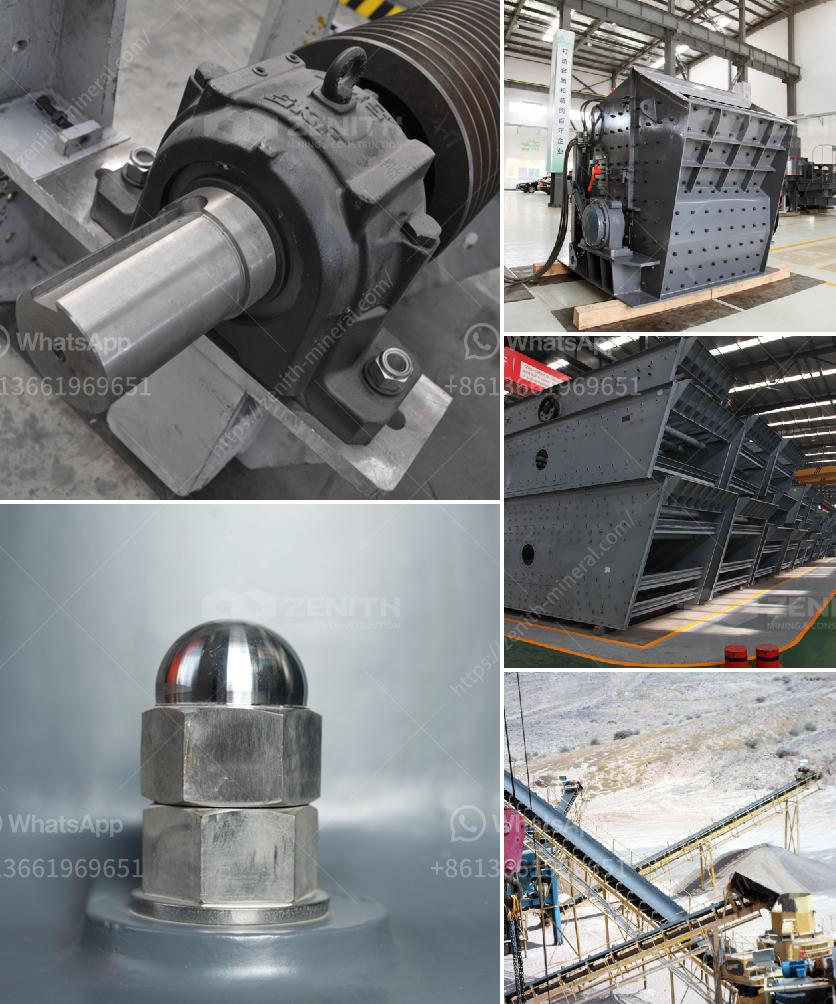

- Pre-Processing: Properly prepare the material before it enters the grinding machine. This can include cleaning, sorting, and pre-sizing the material.

- Efficient Loading and Unloading: Implement efficient systems for loading and unloading the material to minimize downtime.

7. Environmental Control

- Temperature Control: Maintain a stable temperature in the working environment to prevent overheating and ensure consistent performance.

- Dust and Debris Management: Implement systems to manage dust and debris, which can affect the machine's performance and longevity.

8. Upgrading to Advanced Technologies

- High-Pressure Grinding Rolls (HPGR): Consider upgrading to HPGR technology, which can significantly increase production capacity and efficiency.

- Advanced Materials: Use advanced materials for machine components that can withstand higher pressures and temperatures.

9. Process Optimization

- Lean Manufacturing: Implement lean manufacturing principles to streamline the production process and eliminate waste.

- Six Sigma: Use Six Sigma methodologies to identify and eliminate defects in the grinding process.

10. Energy Efficiency

- Energy-Efficient Motors: Use energy-efficient motors to reduce power consumption and increase overall efficiency.

- Power Management: Implement power management systems to optimize energy use and reduce costs.

By addressing these areas, you can significantly increase the production capacity of your stone grinding machine. Each step requires careful planning and execution, but the results can lead to substantial improvements in productivity and efficiency.