It looks like you are interested in a gravity separation process for a 12 tons per hour (tph) rock containing lead, zinc, and copper. Gravity separation is a method of separating two components, either a suspension or dry granular mixture, where separating the components with gravity is sufficiently practical. The process involves the separation of minerals of different specific gravity by their relative movement in response to the force of gravity and one or more other forces, such as centrifugal, magnetic, or buoyant forces.

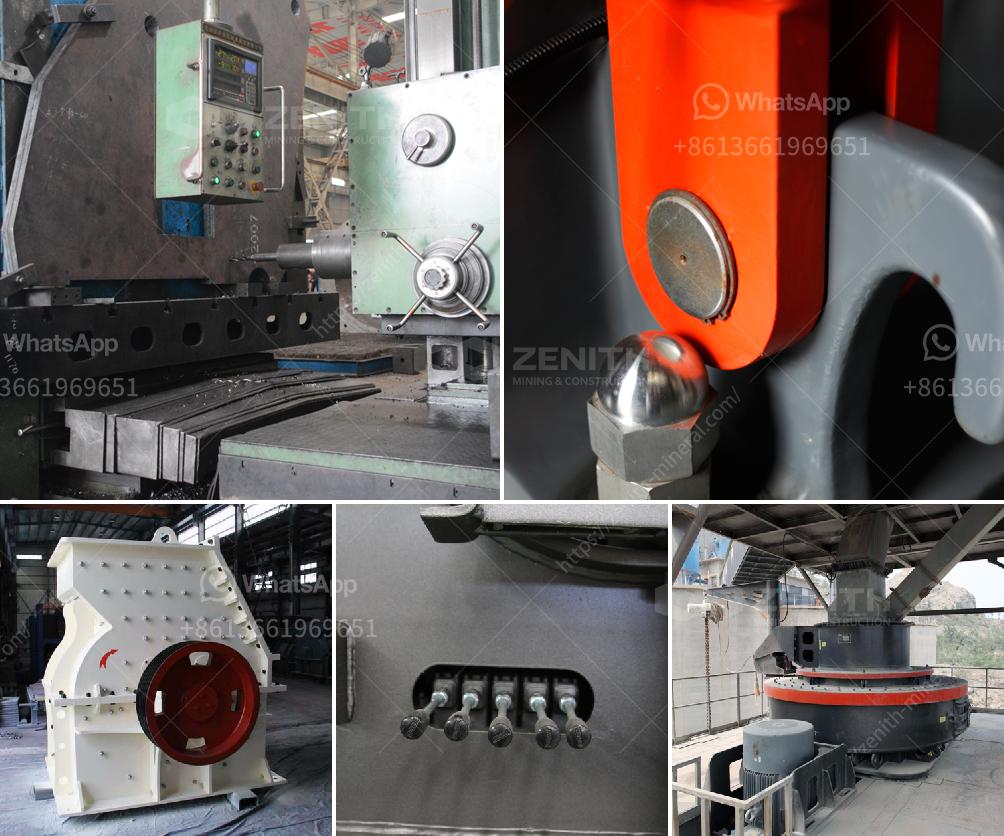

Crushing and Grinding: The ore is first crushed and ground to liberate the valuable minerals from the waste rock. This is typically done using crushers and grinding mills.

Screening: The ground ore is then screened to separate the fine particles from the coarse particles. This can be done using vibrating screens or other types of screening equipment.

Concentration: The fine particles are then subjected to gravity separation. This can be done using various types of equipment, such as jigs, shaking tables, spirals, or centrifugal concentrators. The choice of equipment depends on the specific properties of the ore and the desired outcome.

Separation: The gravity separation equipment separates the valuable minerals from the waste rock based on their specific gravity. The heavier minerals (lead, zinc, copper) will settle faster than the lighter waste rock.

Collection: The separated minerals are then collected and further processed if necessary. This may involve additional steps such as flotation, magnetic separation, or chemical treatment to further purify the minerals.

Tailings Management: The waste rock, or tailings, is managed to minimize environmental impact. This may involve dewatering, storage, and treatment to prevent contamination of water sources.

If you need to implement a simulation or control system for this process, you might use a programming language like Python. Here is an example of how you might structure the code:

# Import necessary libraries

import numpy as np

# Define the properties of the ore

ore_density = 2.7 # g/cm^3

lead_density = 11.34 # g/cm^3

zinc_density = 7.14 # g/cm^3

copper_density = 8.96 # g/cm^3

# Define the separation function

def gravity_separation(ore, densities):

separated_ore = {}

for mineral, density in densities.items():

separated_ore\[mineral\] = ore * (density / ore_density)

return separated_ore

# Define the ore input

ore_input = 12 # tph

# Define the densities of the minerals

densities = {

'lead': lead_density,

'zinc': zinc_density,

'copper': copper_density

}

# Perform the gravity separation

separated_ore = gravity_separation(ore_input, densities)

# Output the results

for mineral, amount in separated_ore.items():

print(f"{mineral.capitalize()}: {amount:.2f} tph")This code defines the densities of the ore and the minerals, then performs a simple gravity separation based on these densities. The results are printed out, showing the amount of each mineral separated from the ore.

Gravity separation is a crucial process in the mining industry, especially for ores containing multiple valuable minerals like lead, zinc, and copper. By understanding the specific properties of the ore and using the appropriate equipment, it is possible to efficiently separate these minerals and maximize the yield. The example code provided demonstrates a basic approach to simulating this process, which can be further refined and expanded based on the specific requirements of the operation.