Sure! Here is a general outline for an 18 tons per hour (18tph) alluvial gold and diamond mining process:

1. Site Preparation

- Surveying and Mapping: Conduct a detailed geological survey to locate alluvial deposits.

- Clearing: Clear the vegetation and topsoil in the mining area carefully, preserving any areas of ecological importance.

2. Excavation and Material Transport

- Excavators: Use heavy machinery like excavators to dig and collect the alluvial material.

- Transport: Transport the excavated material to the processing plant, typically using conveyors or dump trucks.

3. Screening and Washing

- Trommel Screen: Use a trommel screen to separate larger rocks and debris from smaller particles containing gold and diamonds.

- Water Source: Ensure a reliable water source for washing and separating material.

4. Gravity Separation

- Jig Concentrator: For diamond separation, use jig concentrators that can separate material based on density.

- Shaking Tables: Utilize shaking tables to further concentrate gold by separating heavy gold particles from the lighter sand.

5. Final Recovery

- Hand Sorting: For diamonds, after jigging, hand-sorting or optical sorting systems can be employed to pick out diamonds from concentrate.

- Amalgamation/Centrifuge: For gold, the concentrate from the shaking tables can be further processed using a centrifuge or amalgamation to recover fine gold particles.

6. Waste Management

- Tailings Storage: Develop a proper tailings storage facility to manage waste material and prevent environmental contamination.

- Rehabilitation: Plan for site rehabilitation post-mining, including re-soiling and re-vegetation of the mined area.

7. Safety and Compliance

- Health and Safety: Implement robust health and safety protocols to ensure the protection of workers.

- Legal Compliance: Ensure all mining activities comply with local, regional, and international mining laws and regulations.

8. Continuous Monitoring and Optimization

- Efficiency Monitoring: Regularly monitor the efficiency of each stage of the process and make adjustments as necessary.

- Technological Updates: Stay updated with new technologies that might improve recovery rates and reduce operational costs.

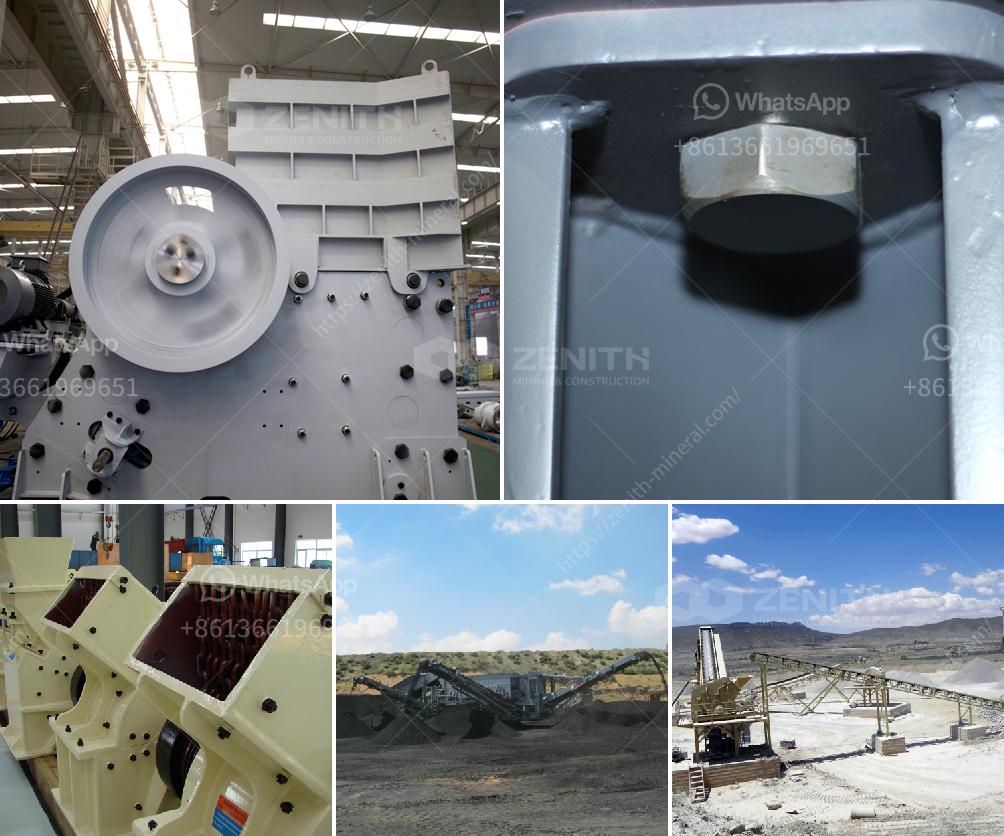

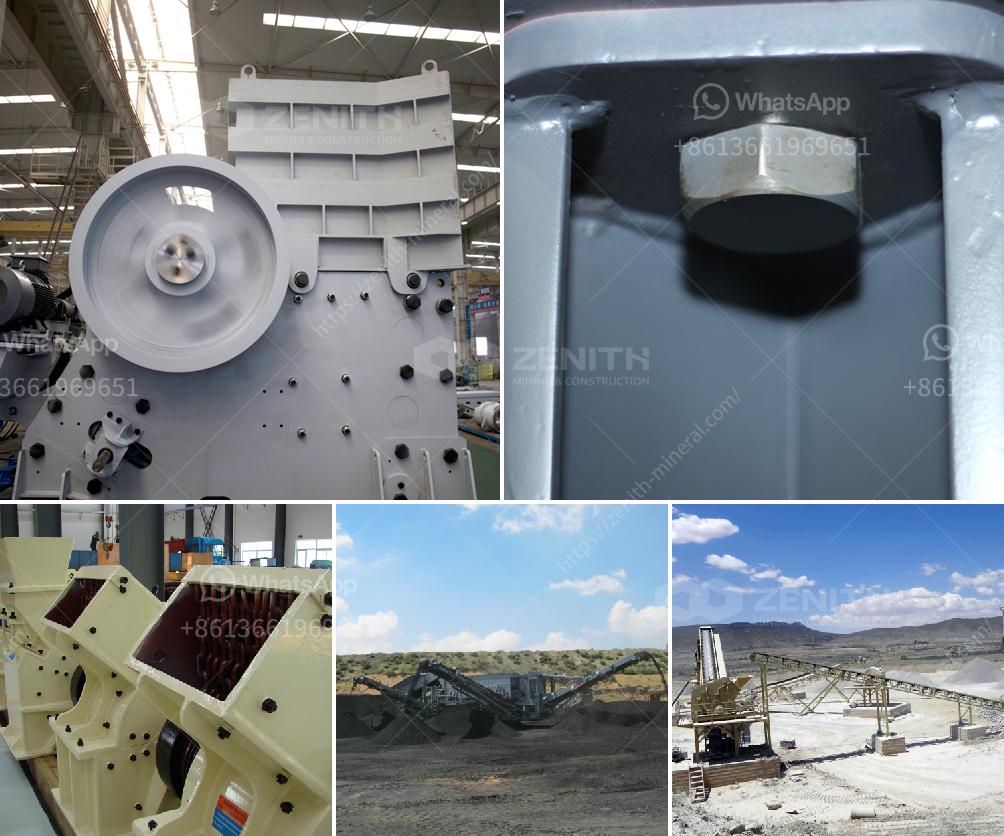

Example Equipment List:

- Excavators

- Conveyors/Dump trucks

- Trommel Screen

- Jig Concentrators

- Shaking Tables

- Centrifuge

- Hand Sorting Equipment

By following these steps and utilizing the appropriate equipment, you can establish an efficient 18tph alluvial gold and diamond mining operation.