Mining copper involves several types of mechanical equipment to efficiently extract and process the ore. The main equipment includes:

- Drilling Rigs: Used to drill holes for explosives in open-pit and underground mining.

- Blasting Tools: Explosives and blasting tools are used to break up the rock to access the copper ore.

- Excavators: Heavy machinery such as hydraulic shovels and backhoes are used to move large quantities of material.

- Loaders: Loaders, including front-end loaders, are used to load the extracted copper ore into haul trucks.

- Haul Trucks: Large, heavy-duty trucks used to transport the blasted copper ore from the mining site to the processing facilities.

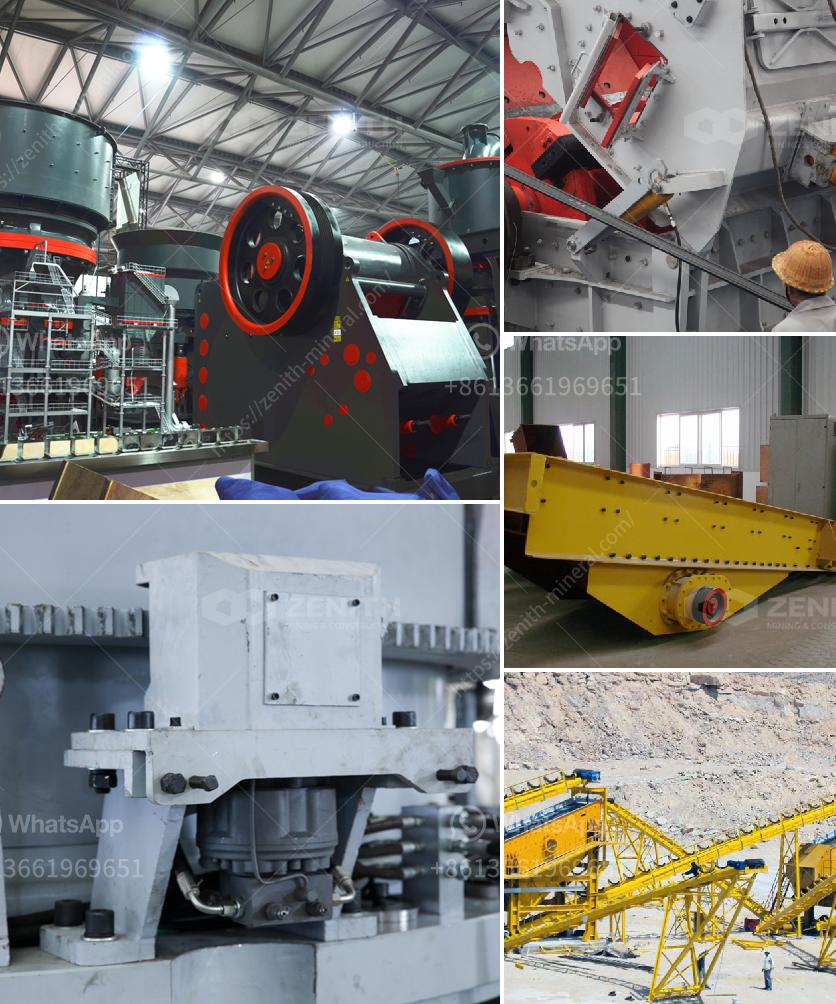

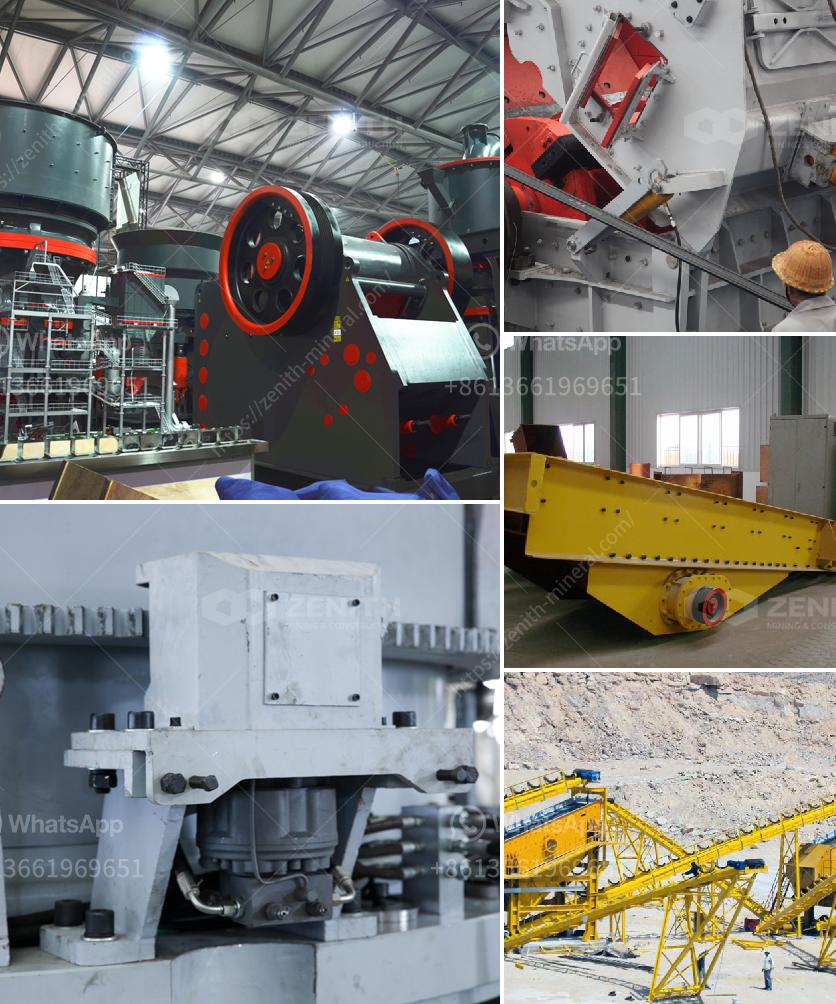

- Crushers: Equipment used to crush the ore into smaller, more manageable pieces.

- Mills: Mechanical mills, such as SAG (Semi-Autogenous Grinding) mills and ball mills, are used to further grind the crushed ore.

- Flotation Cells: Equipment used in the froth flotation process to separate copper minerals from the waste rock.

- Thickeners: Used to remove excess water from the copper concentrate.

- Filtering and Drying Equipment: Used to dry the copper concentrate before it is sent to smelters.

Depending on the specific methods employed, additional equipment such as conveyors, feeders, pumps, and surveying instruments may also be required.

These pieces of machinery work in coordination to effectively mine and process copper ore, ensuring the efficient extraction of valuable resources.