A 25tph (tons per hour) chromite ore concentrating plant is an industrial facility designed to process chromite ore and increase its concentration or purity through various beneficiation techniques. Here's a brief overview of what such a plant encompasses:

-

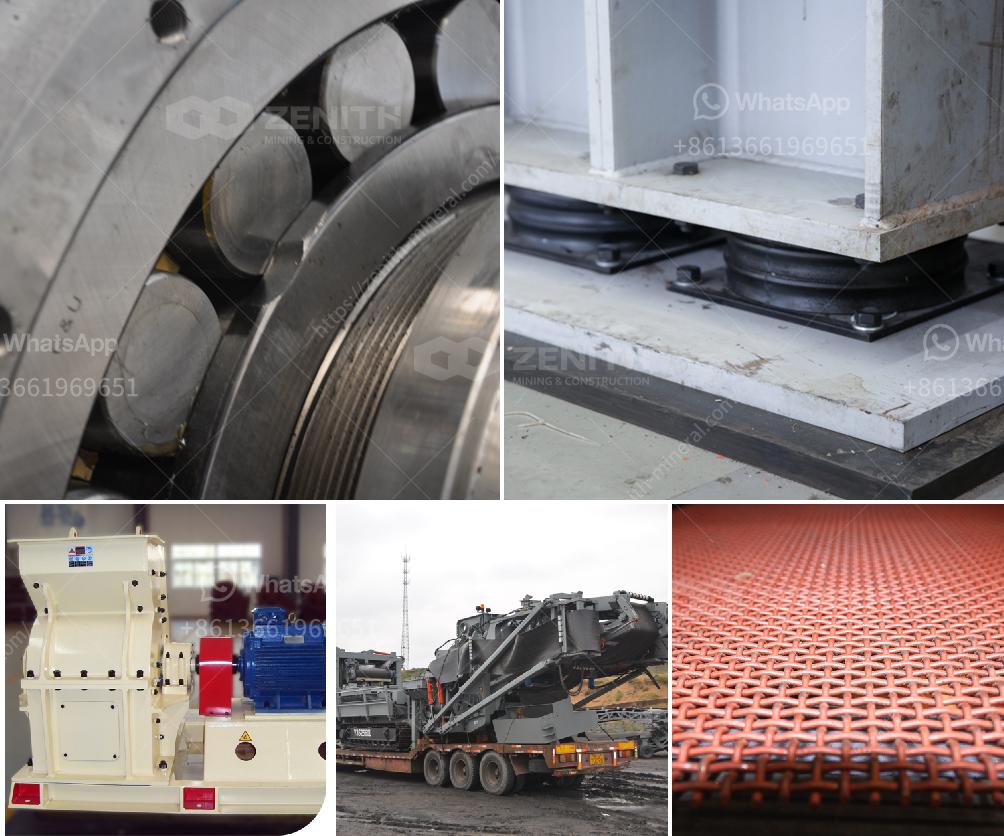

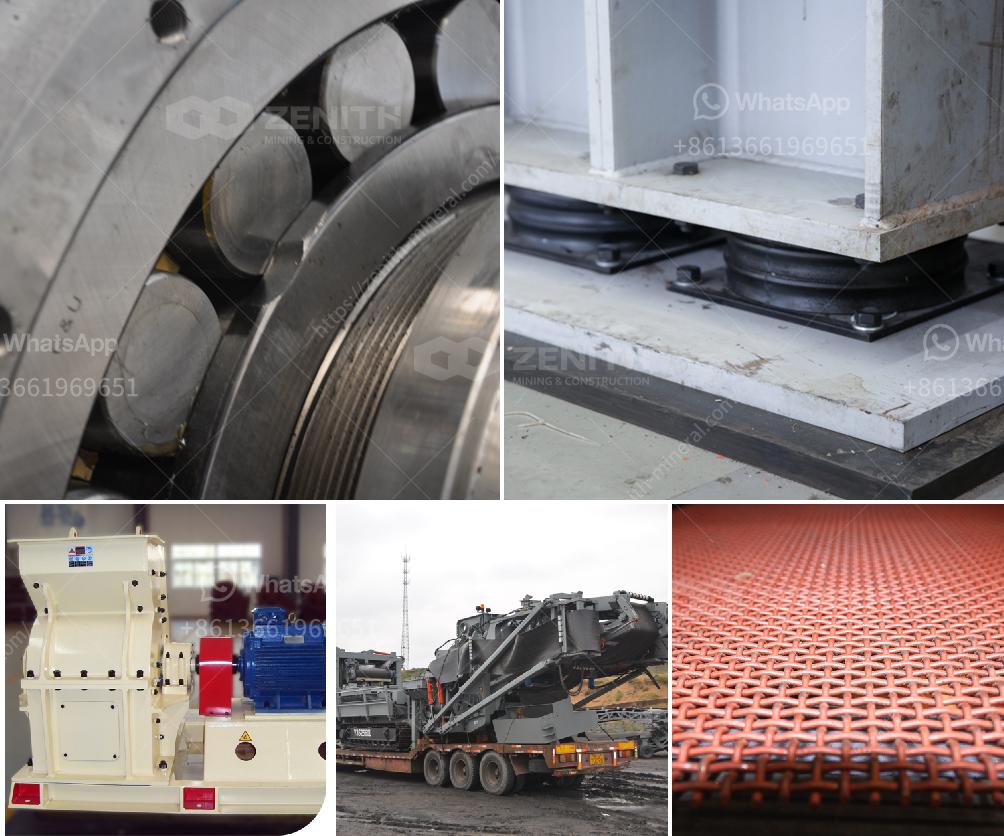

Crushing and Grinding:

- Initial stages involve crushing the chromite ore to reduce its size for easier handling and processing.

- Further grinding to achieve the desired particle size for optimal separation.

-

Screening:

- Use of vibrating screens to classify the crushed and ground ore into different size fractions.

-

Gravity Separation:

- Utilizing gravity separators such as jigs, spirals, shaking tables, and concentrators to separate heavy chromite particles from lighter gangue minerals.

-

Magnetic Separation:

- In some plants, magnetic separators may be used if the chromite ore and associated materials exhibit different magnetic properties.

-

Flotation:

- Involves adding chemicals (reagents) to a slurry of ground ore to selectively attach to chromite particles and float them for collection.

-

Dewatering:

- Processes like thickening, filtration, and drying to remove excess water from the concentrated ore.

-

Tailings Management:

- Handling and disposal of leftover materials from the beneficiation process in an environmentally responsible manner.

-

Control Systems:

- Automation and monitoring systems for efficient operation and safety.

Key Considerations:

- Ore quality and mineralogy significantly affect the choice of processing methods.

- Environmental regulations require proper waste management and pollution control practices.

- Energy efficiency and cost-effectiveness are crucial for the plant’s sustainability.

Would you like more detailed information on any of the specific stages or equipment used in this type of plant?