A 42 TPH (tons per hour) rock gold processing plant is typically a facility that processes rock containing gold to extract the precious metal. Here’s a brief overview of what such a plant generally involves:

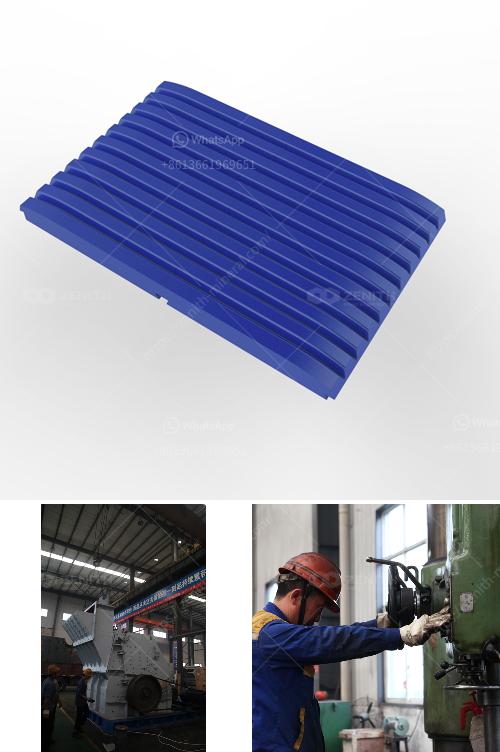

Crushing and Grinding: This is the initial stage where large rocks are crushed and then ground into finer particles to prepare them for further processing.

Gravity Separation: After crushing, the ground material might undergo gravity separation which uses centrifugal force, shaking tables, or jigs to concentrate the heavier gold particles away from lighter waste material.

Flotation: In some cases, flotation is used where chemicals are added to a slurry of ground ore that makes the gold-containing minerals adhere to bubbles and rise to the surface where they can be skimmed off.

Leaching and Adsorption: For finer gold particles or to achieve higher recovery percentages, the material might be subjected to a leaching process using cyanide or other reagents. The gold-cyanide solution is then processed to extract and concentrate gold using activated carbon or other adsorbents.

Electrowinning or Precipitation: The gold is then recovered from the solution by electrowinning or precipitation. In electrowinning, an electric current is passed through the solution to deposit gold onto electrodes, while precipitation commonly involves using zinc dust in a Merrill-Crowe process.

Smelting and Refining: The concentrated gold is then melted in a furnace to produce doré bars which are then sent to a refinery for further purification.

Water and Waste Management: Effective water management and waste disposal systems are crucial for minimizing the environmental impact of the processing plant.

This plant would be engineered to handle 42 tons of rock per hour, involving a range of equipment customized to meet specific mineralogical characteristics of the rock and the desired purity levels of the final gold product.