A 50 tons per hour (tph) alluvial gold washing plant is designed to process gold-laden alluvial deposits. Here are some essential components and their functionalities:

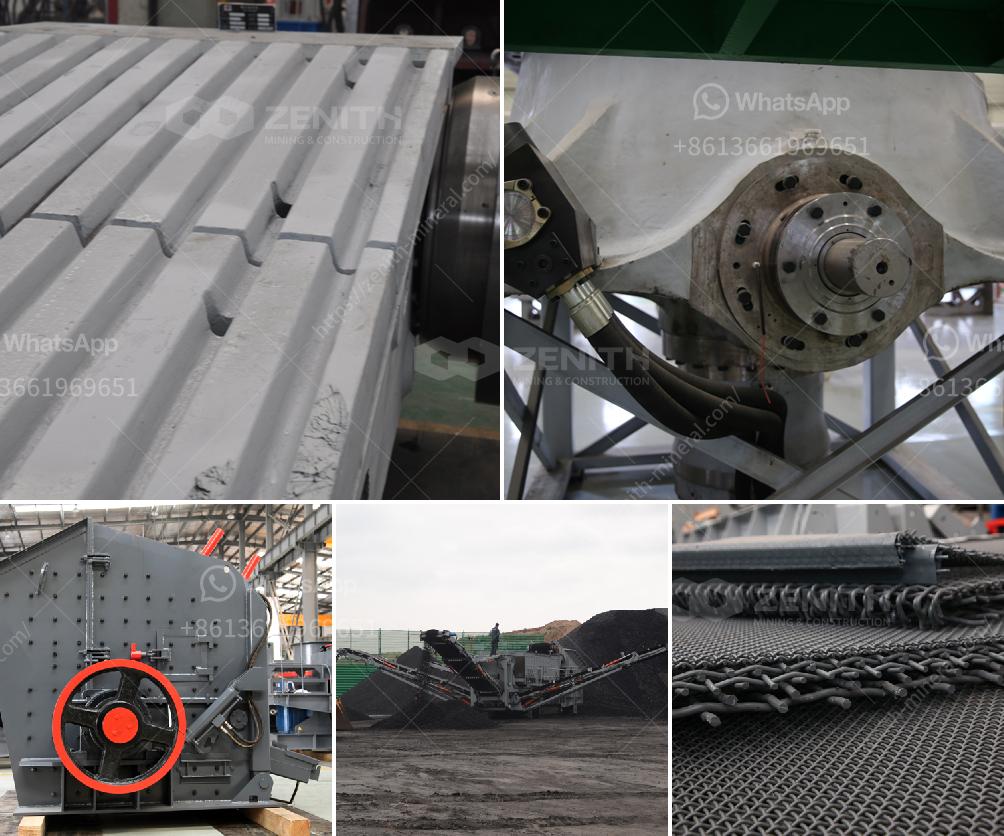

Grizzly Feeder (or Trommel Screen): This is used to remove larger rocks and debris before the finer materials enter the system.

Scrubber/Log Washer: Cleans and breaks down clay and soil to ensure the gold is freed from the surrounding material.

Gold Recovery Equipment:

Water Pump and Recycling System: Ensure constant water flow for the washing and separation processes. Recycling systems may be employed to reduce water consumption.

Conveyor Belts: Transport material between different stages of the plant.

Concentrators: Such as centrifugal concentrators which further enhance gold recovery from fine materials.

In design considerations:

Setting up such a plant involves a comprehensive planning process to maximize gold recovery while minimizing environmental impact.