Building a sand and gravel wash plant involves several steps and considerations. Here’s a general guide to help you get started:

1. Site Selection and Permits:

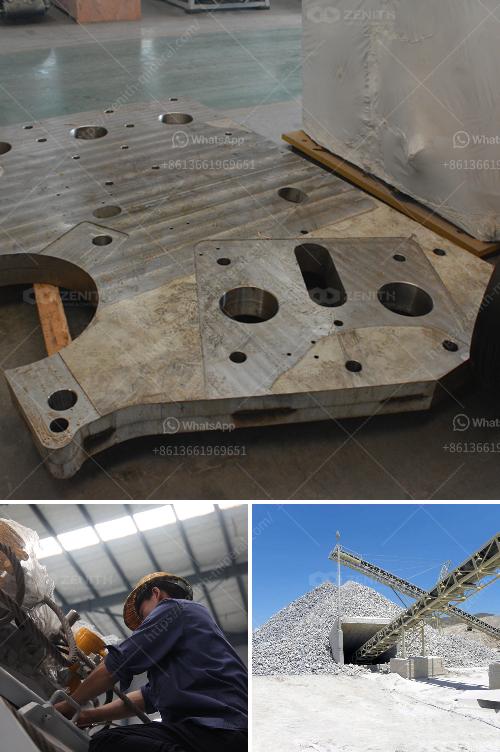

- Identify the Site: Choose a location that has an abundant supply of raw materials (sand and gravel) and is accessible for transportation.

- Environmental Analysis: Conduct necessary environmental assessments and impact studies.

- Obtain Permits: Secure all required permits and comply with local regulations and zoning laws.

2. Design the Layout:

- Plan the Plant Layout: Design an efficient flow layout that minimizes handling and maximizes space utilization.

- Include Key Components:

- Feed Hopper: Where raw materials are initially loaded.

- Conveyors: To transport materials between different stages.

- Washing Systems: Including sprayers, screens, and classifiers to clean the materials.

- Settling Ponds: For water treatment and sediment capture.

- Storage Bins: For finished product storage.

3. Choosing Equipment:

- Feeders and Conveyors: To move raw materials into the washing system.

- Screens and Classifiers: To separate and classify materials by size.

- Washing Equipment:

- Log Washers, Scrubbers, or Trommels: For washing away dirt and clay.

- Cyclones or Hydroclones: To further clean and separate fine particles.

- Water Recycling Systems: To manage and recycle the water used in the process, reducing environmental impact.

- Pumping Systems: To transport water throughout the plant.

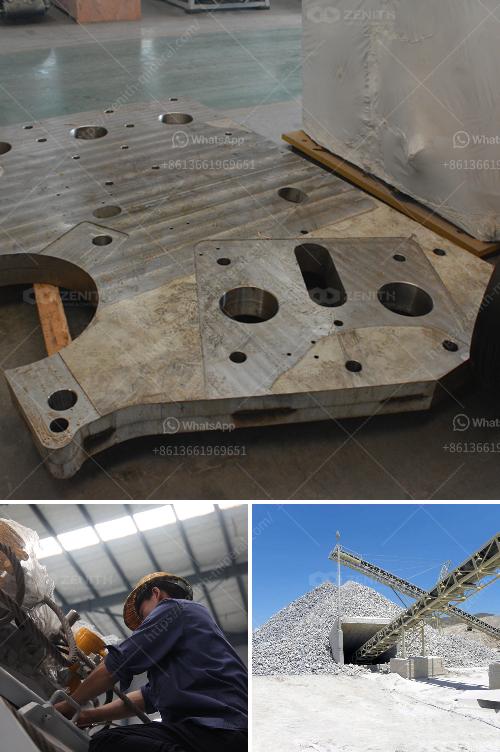

4. Installation:

- Foundation Work: Prepare the area for heavy machinery with proper foundations and drainage systems.

- Assembly: Assemble the components according to manufacturer guidelines or with professional help.

- Electrical and Plumbing: Ensure that the plant has the necessary power and water supply connections installed.

5. Operational Setup:

- Training: Train staff on operating procedures and safety standards.

- Safety Measures: Implement safety protocols and install necessary safety equipment.

- Trial Runs: Conduct test runs to ensure all systems work efficiently and make necessary adjustments.

6. Maintenance and Monitoring:

- Regular Maintenance: Establish a maintenance schedule for all machinery to prevent breakdowns and prolong life.

- Monitoring Systems: Install monitoring devices to track the performance and health of the equipment.

7. Sustainability Practices:

- Water Treatment: Employ effective recycling and treatment systems to minimize water usage.

- Dust Control: Implement dust suppression techniques to reduce airborne particles.

- Waste Management: Handle and dispose of waste materials responsibly.

Conclusion:

Building a sand and gravel wash plant requires careful planning, design, and execution. Adhering to best practices and maintaining a focus on sustainability can help ensure efficient and environmentally friendly operations. If necessary, consult with industry experts or engineers to tailor the setup to specific site conditions and requirements.