Building a quartz crusher can be an involved process, depending on the scale of the crushing operation you intend to create. Below is a simplified guide to give you an idea of the general steps and considerations:

-

Research and Planning:

- Understand the scale of your operation. Is it for small-scale hobby projects or industrial-level crushing?

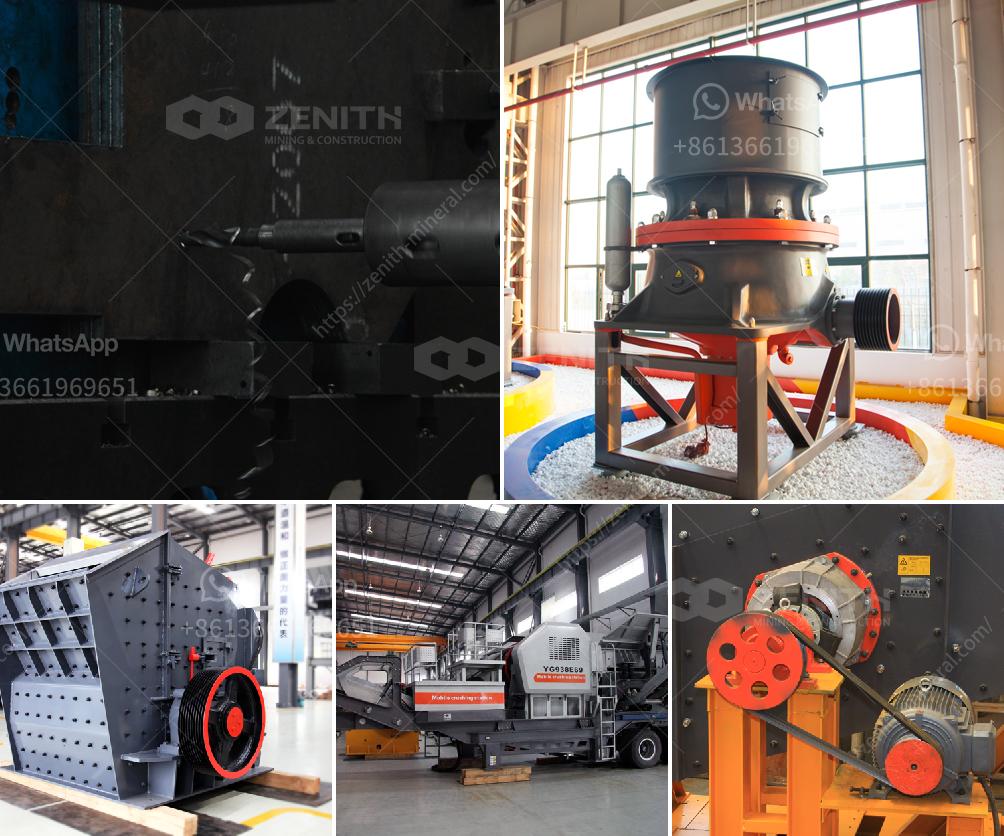

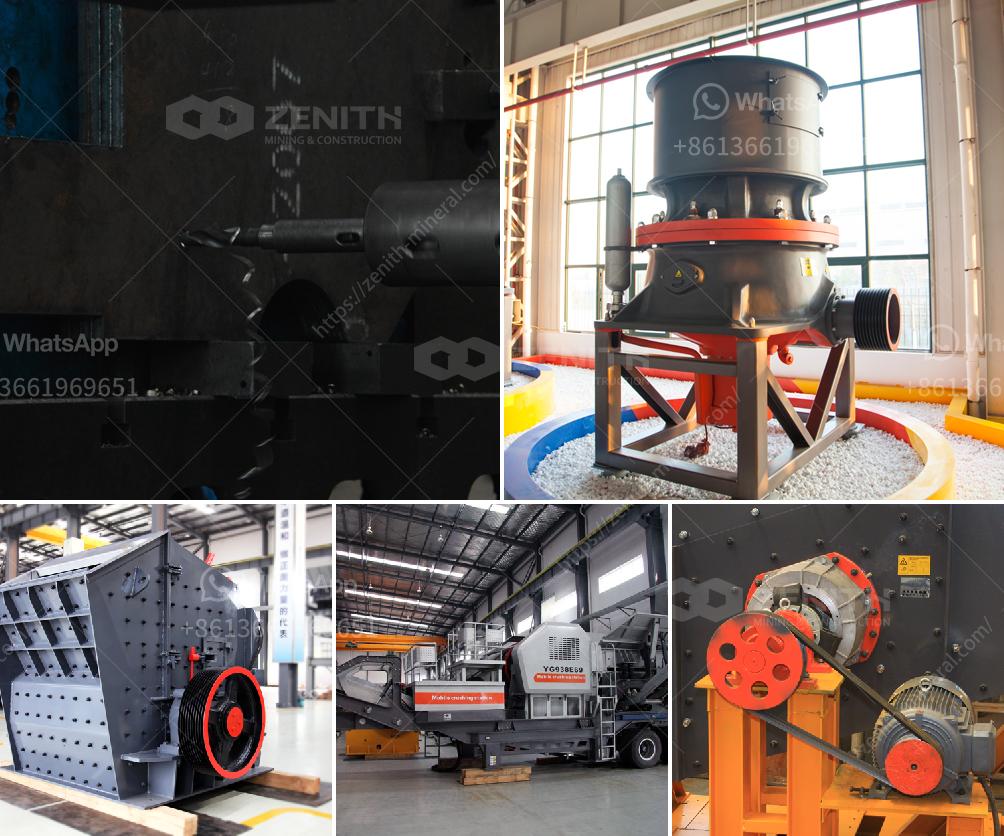

- Determine the type of crusher you'll need. Common types include jaw crushers, impact crushers, and hammer crushers.

-

Gather Materials and Tools:

- Steel for the crusher’s frame and housing.

- Hardened steel or industrial-grade materials for the crushing surfaces.

- Motor and power supply adequate for your chosen crusher type.

- Bearings, belts, nuts, bolts, and other fasteners.

-

Design the Crusher:

- Create or obtain detailed plans for the crusher. These should include detailed measurements and layouts.

- You can often find plans online or at engineering resources.

-

Construct the Frame:

- Cut and weld the steel to form the base and frame of the crusher.

- Ensure the frame is strong and rigid enough to withstand significant forces during crushing.

-

Install the Crushing Mechanism:

- For a jaw crusher: Install the fixed jaw and the movable jaw. These may involve welding or bolting into place.

- For an impact crusher: Assemble the hammers and impact plates.

- For a hammer crusher: Attach the hammers to the central rotating shaft.

-

Mount the Motor and Power System:

- Attach the motor securely to the frame.

- Couple the motor to the crushing mechanism using appropriate pulleys, belts, or direct coupling systems.

- Ensure the motor is powerful enough to drive the crushing mechanism effectively.

-

Safety and Testing:

- Add safety guards around rotating parts and other danger zones.

- Test the crusher with a small amount of quartz to ensure everything is functioning correctly.

- Make adjustments as necessary to optimize performance.

-

Fine-Tuning:

- Make any necessary adjustments to the gap settings or feed mechanism to fine-tune the crusher’s performance.

- Ensure all parts are aligned and secured properly to avoid malfunction during operation.

Safety Considerations:

- Always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and ear protection.

- Ensure proper ventilation if crushing indoors to avoid dust inhalation.

- Follow all relevant safety regulations and guidelines.

Legal and Environmental Compliance:

- Check local regulations regarding mineral processing equipment and ensure your crusher complies.

- Consider the environmental impact and manage dust and noise pollution accordingly.

This simplified guide is intended for basic educational purposes. For a more in-depth construction and detailed plans, consulting with a mechanical engineer or a professional in the field is recommended.