In copper processing in Zambia, several types of crushers are utilized to reduce the size of the ore for easier handling and processing. The primary crushers used include:

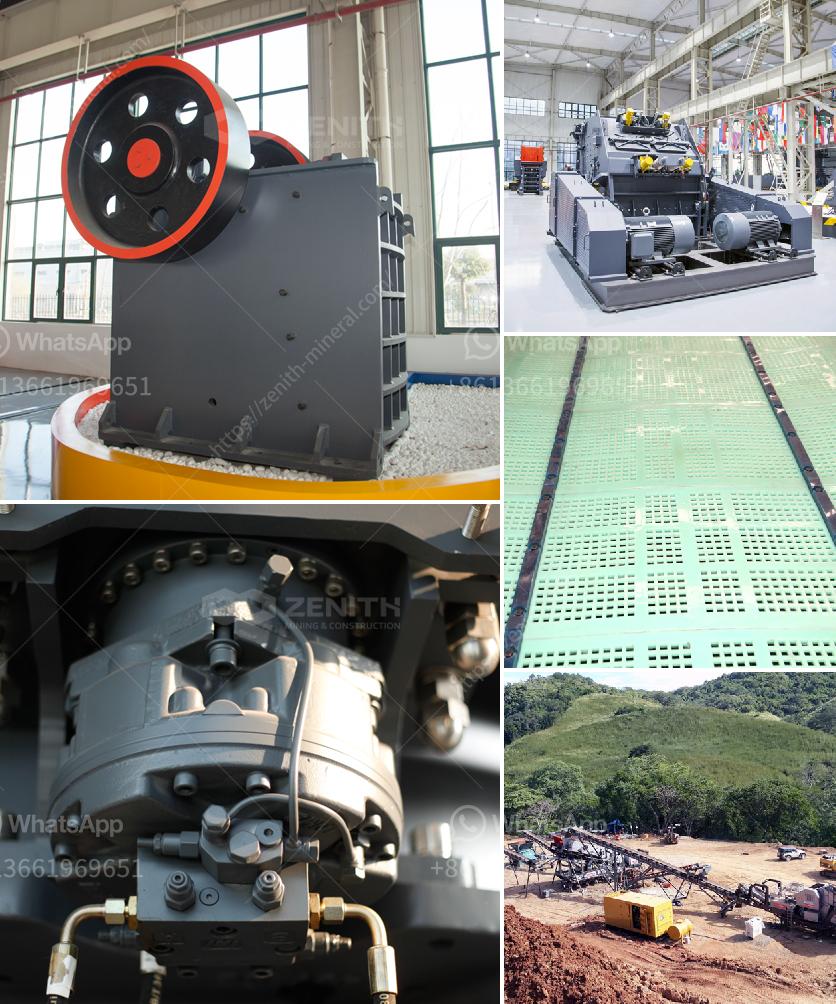

Jaw Crushers: These are used for the initial crushing of large chunks of copper ore. They can handle large pieces of rock and reduce them to a manageable size.

Gyratory Crushers: Often used as primary crushers, gyratory crushers can handle significant capacities and offer high throughput. They are ideal for processing hard and abrasive materials like copper ore.

Cone Crushers: These are used as secondary or tertiary crushers. They work well for secondary crushing as they can further reduce the size of the materials after primary crushing. Cone crushers are also effective for creating finely crushed products.

Impact Crushers: Sometimes used after jaw or gyratory crushers, impact crushers involve the use of high-speed impact to break down materials, making them suitable for producing finer, evenly shaped particles.

Roll Crushers: These are less common but can be used for secondary crushing of softer ore materials. They use compression and offer uniform size reduction.

Each type of crusher has its specific use case depending on the processing stage and the nature of the copper ore being handled.