The running cost for a jaw crusher can vary significantly depending on factors such as the size of the machine, the materials being processed, the desired output, and the maintenance required. Here are some of the main factors that can influence the cost:

Electricity Usage: Power consumption can be a significant part of the operating cost, often depending on the efficiency and power rating of the crusher.

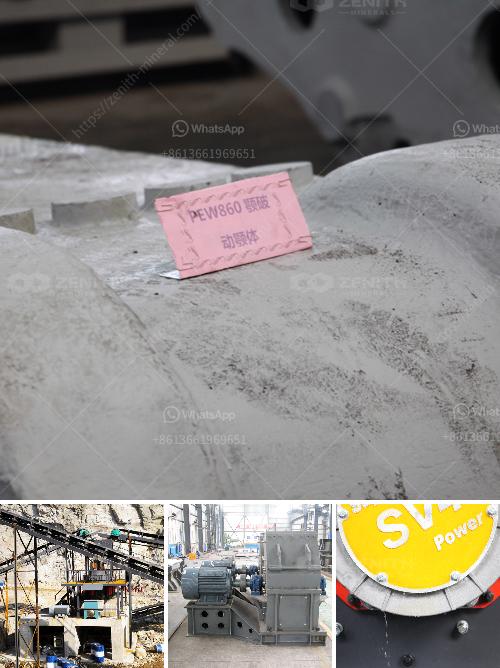

Wear and Tear: Jaw crushers encounter substantial wear on their jaws and require regular maintenance to ensure longevity. The cost of wear parts (like jaw plates) is an important factor to consider.

Labor Costs: Skilled operators are needed to run the machinery and perform maintenance, impacting the overall running cost.

Maintenance and Repairs: Routine maintenance and unexpected repairs can contribute to operational costs. Regular servicing helps prevent breakdowns and ensures the machinery operates efficiently.

Lubrication and Consumables: Regular lubrication is essential for the smooth operation of the jaw crusher. Consumable items like oil and filters add to the costs.

Depreciation: Over time, the value of the jaw crusher will depreciate. This should be factored in as a cost of the equipment.

Without specific details, it is challenging to provide an exact cost. However, operators typically assess running costs based on a combination of these factors and the specific context of their crushing operation.