Improving the production capacity of a crusher involves several key strategies across various aspects of its operation. Here are some effective ways to enhance crusher performance:

-

Regular Maintenance:

- Schedule routine maintenance to prevent wear and tear.

- Keep the crusher's components well-lubricated and ensure that all parts are in good working condition.

-

Optimize Feed Material:

- Ensure the material fed into the crusher is pre-screened to remove fines, enhancing throughput.

- Use a feeder that can deliver a consistent and even flow of material.

-

Adjust Crusher Settings:

- Fine-tune the closed-side setting (CSS) to achieve a balance between throughput and product size.

- Utilize automation systems to monitor and adjust settings in real-time.

-

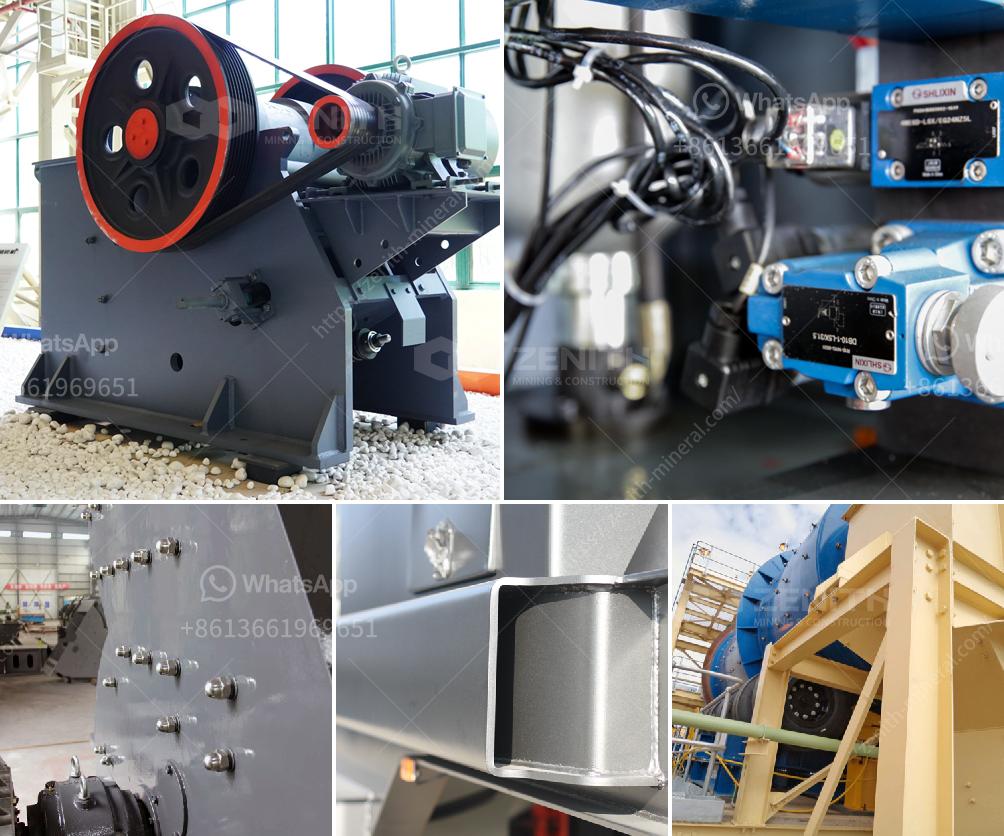

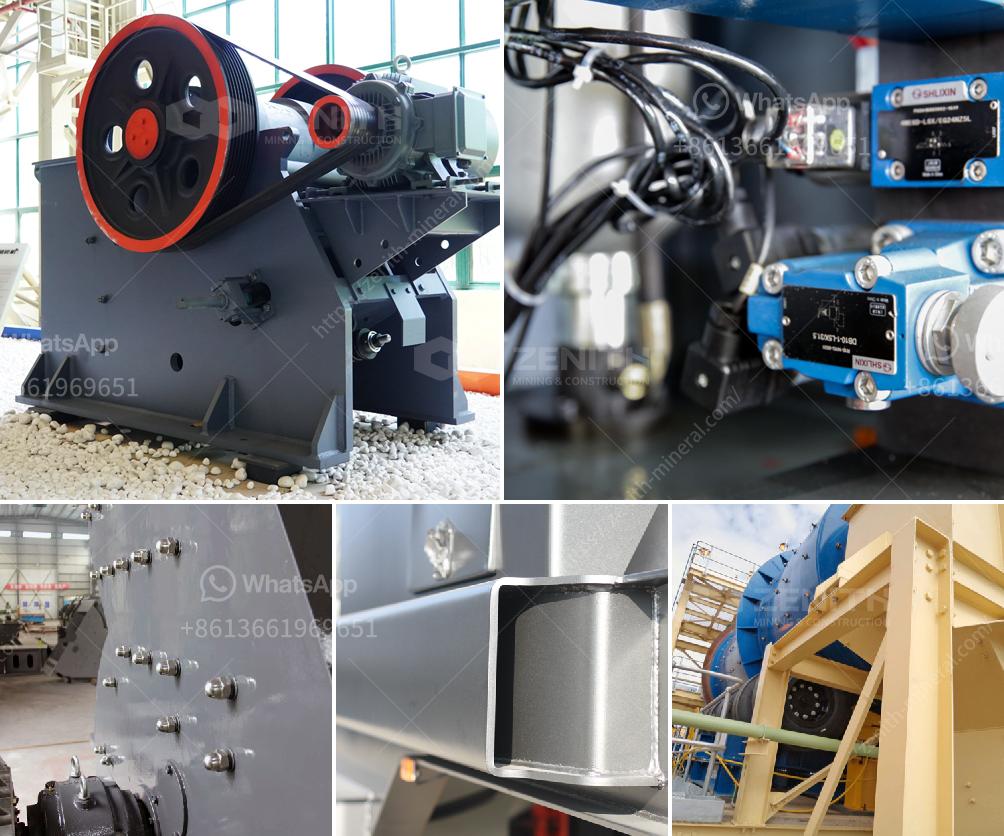

Upgrade Equipment:

- Invest in more advanced or larger capacity crushers if the current model no longer meets production demands.

- Consider technologies that improve crushing efficiency, such as hydraulic relief systems and automation.

-

Improve Feed Design:

- Design the feed chute and hopper to minimize blockages and promote a consistent material flow.

- Ensure proper alignment and angle to facilitate smooth entry into the crusher.

-

Staff Training:

- Regularly train operators and maintenance personnel on best practices and new technologies.

- Encourage a proactive approach to identifying and addressing potential issues.

-

Monitor and Analyze Performance:

- Use data analytics and monitoring tools to track performance metrics like throughput, motor loading, and wear rates.

- Continuously analyze this data to identify areas for improvement and implement changes accordingly.

-

Upgrade Screening and Conveying Systems:

- Ensure that the crusher is part of an efficient system where material is effectively screened and conveyed.

- This reduces recirculation load and allows the crusher to operate more efficiently.

By focusing on these strategies, you can significantly improve the production capacity of your crusher and optimize its overall performance.