The maintenance schedule for a crushing plant can vary depending on the specific type of plant, its components, and its operational conditions. However, general maintenance practices for crushing plants can be summarized as follows:

Daily Maintenance:

- Inspection: Conduct a thorough inspection of the plant for any signs of wear, damage, or unusual noises.

- Cleanliness: Ensure the plant and the surrounding areas are kept clean to prevent buildup and contamination.

- Lubrication: Check and maintain appropriate lubrication levels in bearings and other moving parts.

- Safety Checks: Verify that all safety devices and emergency stops are functioning correctly.

Weekly Maintenance:

- Bolts and Fasteners: Inspect and tighten any loose bolts and fasteners.

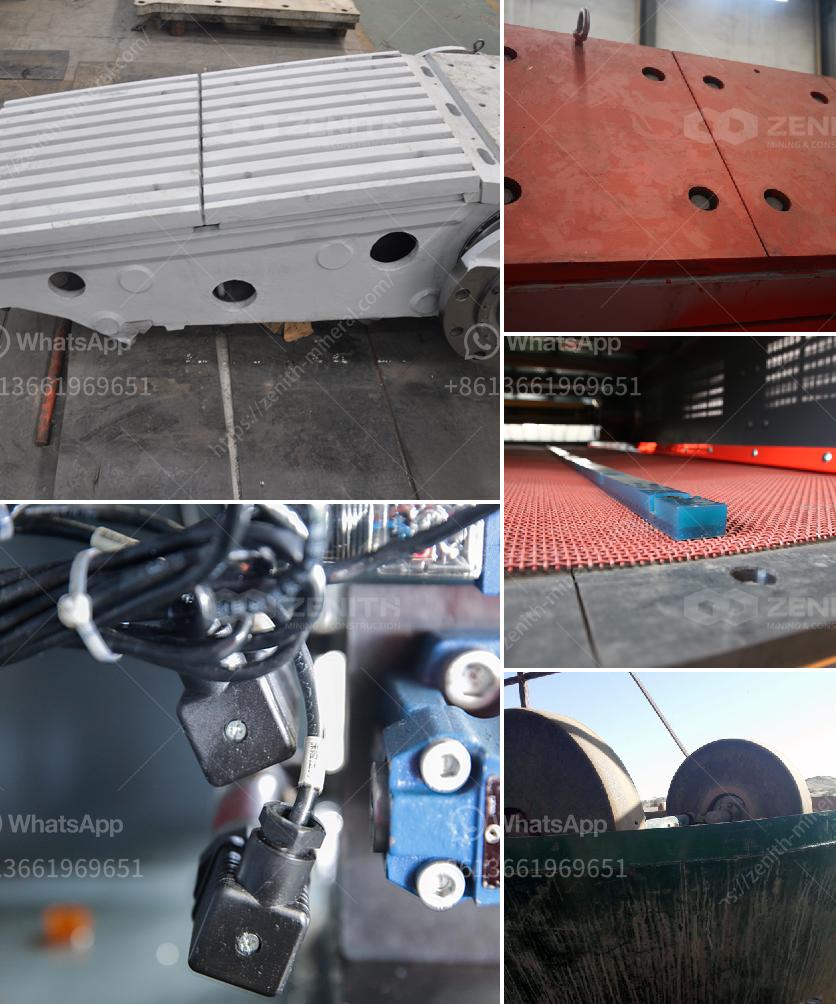

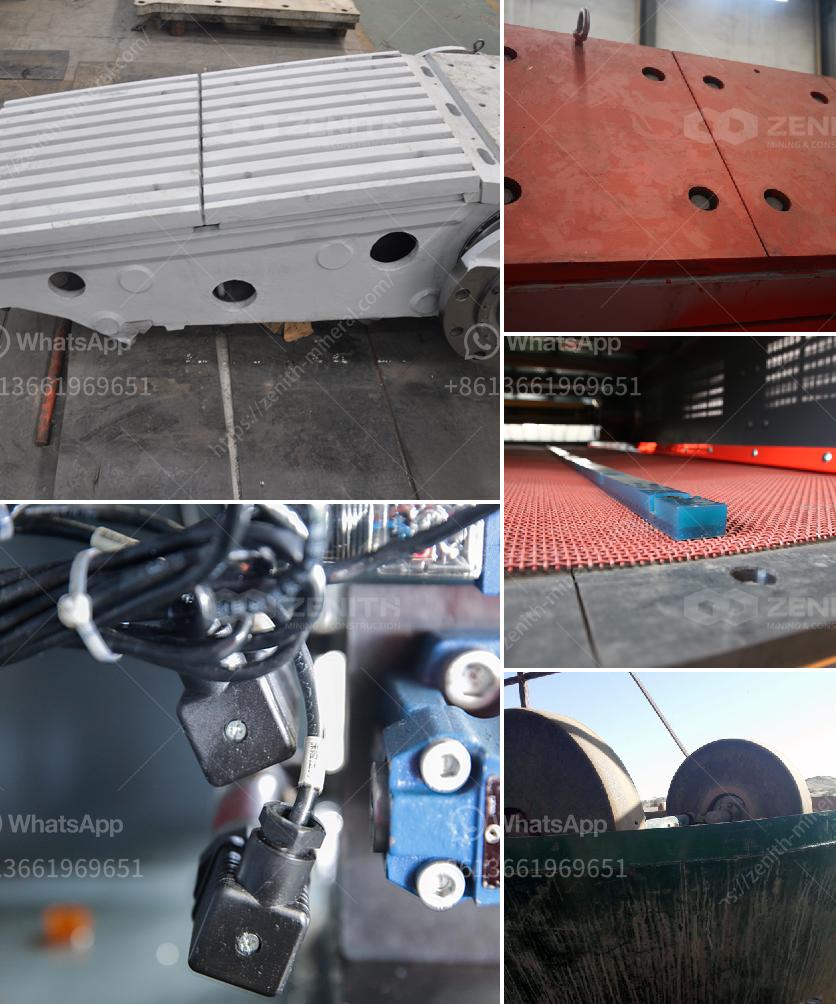

- Belts and Conveyors: Check the condition of conveyor belts, pulleys, and rollers.

- Screening Components: Inspect screen media for wear and replace if necessary.

- Dust Suppression: Ensure that dust suppression systems are working effectively.

Monthly Maintenance:

- Wear Parts: Inspect and replace wear parts such as jaw plates, cone liners, and impact plates.

- Hydraulic Systems: Check hydraulic fluid levels and inspect for leaks.

- Electrical Components: Inspect electrical wiring and connections for signs of damage or wear.

- Motors and Bearings: Examine motors and bearings for overheating and vibration.

Quarterly Maintenance:

- Vibration Analysis: Conduct a vibration analysis to predict potential failures in rotating equipment.

- Alignment: Check and correct the alignment of shafts and pulleys.

- Structural Integrity: Inspect the structural integrity of the plant's framework and support structures.

Annual Maintenance:

- Comprehensive Inspection: Perform a thorough, top-to-bottom inspection of the entire plant.

- Major Repairs: Address any major repairs or replacements that are necessary.

- System Overhaul: Overhaul critical components such as crushers, feeders, and screens.

- Documentation: Review and update maintenance records and logs.

Additional Tips:

- Always follow the manufacturer’s recommendations for maintenance intervals and procedures.

- Keep detailed maintenance records to help identify patterns and predict future maintenance needs.

- Train personnel adequately in maintenance procedures and safety standards.

- Utilize predictive maintenance technologies, like condition monitoring and diagnostics, to preemptively tackle issues before they result in downtime.

Regular maintenance not only ensures the longevity of the equipment but also enhances efficiency and safety in the crushing plant operations.