The cost of artificial sand projects can vary widely based on several factors including the scale of the project, location, quality of sand required, machinery and technology used, labor costs, and transportation. Generally, the expenses can be broadly categorized as follows:

-

Capital Expenditure (CapEx):

- Land Acquisition: Cost of purchasing or leasing the land.

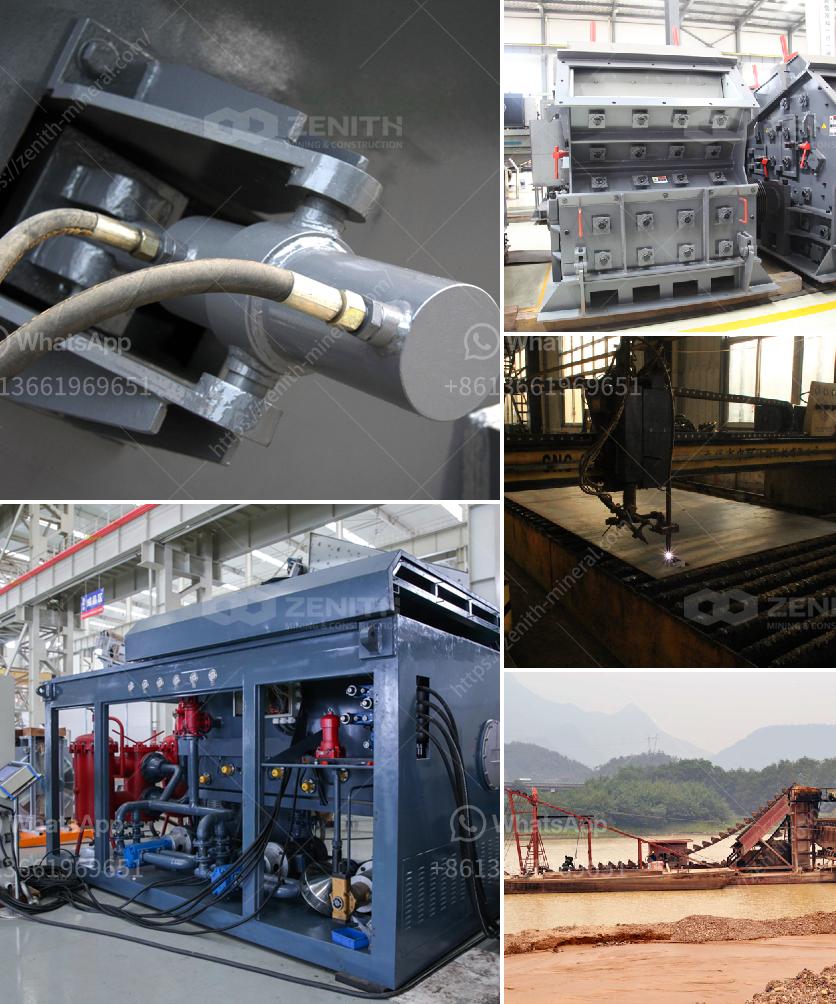

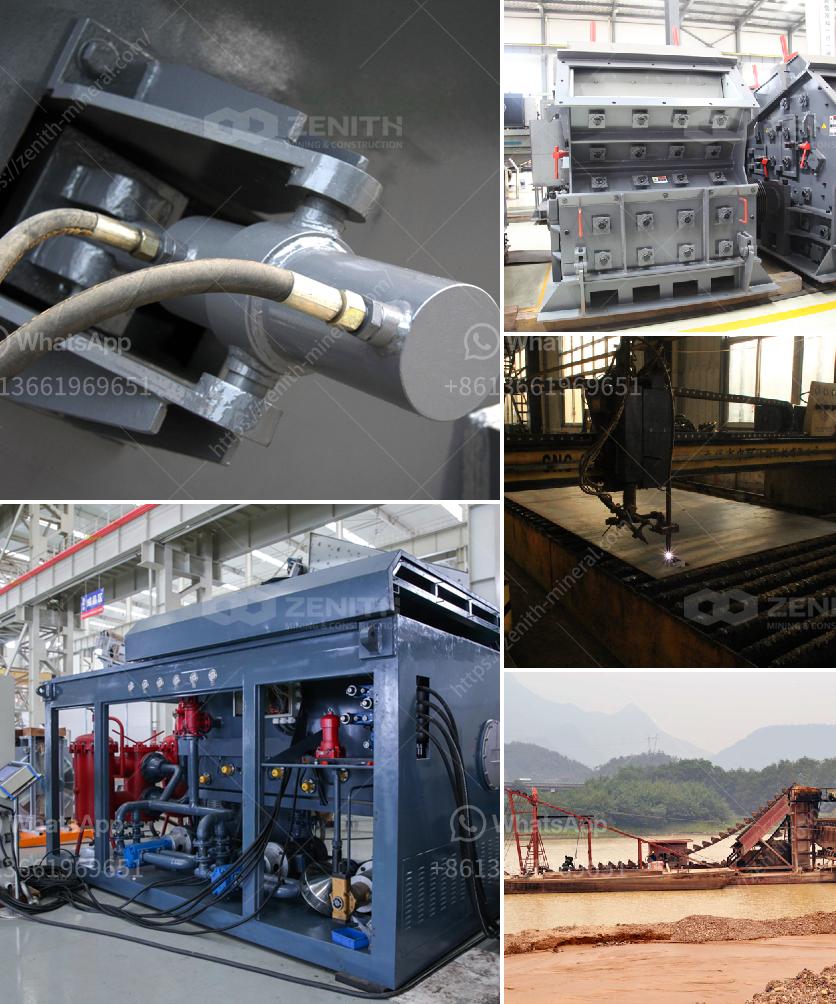

- Machinery and Equipment: Costs related to crushers, screens, conveyors, and other necessary machinery.

- Infrastructure: Installation of necessary infrastructure such as power supply, water supply, and access roads.

-

Operational Expenditure (OpEx):

- Raw Materials: Cost of raw feed material (like rocks).

- Labor: Salaries and wages of workers involved in the project.

- Maintenance: Regular maintenance of machinery and equipment.

- Utilities: Electricity, water, and other utilities required for the operation.

-

Regulatory and Miscellaneous Costs:

- Permits and Licenses: Fees for obtaining necessary operational permits and licenses from local authorities.

- Environmental Compliance: Costs related to ensuring environmental regulations are met, including possible impact assessments.

- Marketing and Distribution: Expenses for marketing the artificial sand and transporting it to buyers.

For a more specific cost estimate, detailed project planning and cost analysis tailored to the particular project is necessary. Typically, smaller projects could range from a few hundred thousand dollars to a few million dollars, while larger, industrial-scale projects could require tens of millions of dollars.

Consulting with industry experts and conducting a feasibility study can provide a more accurate and detailed cost breakdown tailored to your particular circumstances.