A sand sieving machine is a device designed to separate sand particles based on size. This machine is commonly used in construction, mining, and various industrial applications where the separation of fine particles from coarse particles is necessary. The primary purpose of a sand sieving machine is to ensure that the sand used in construction or other processes is of uniform size and free from impurities.

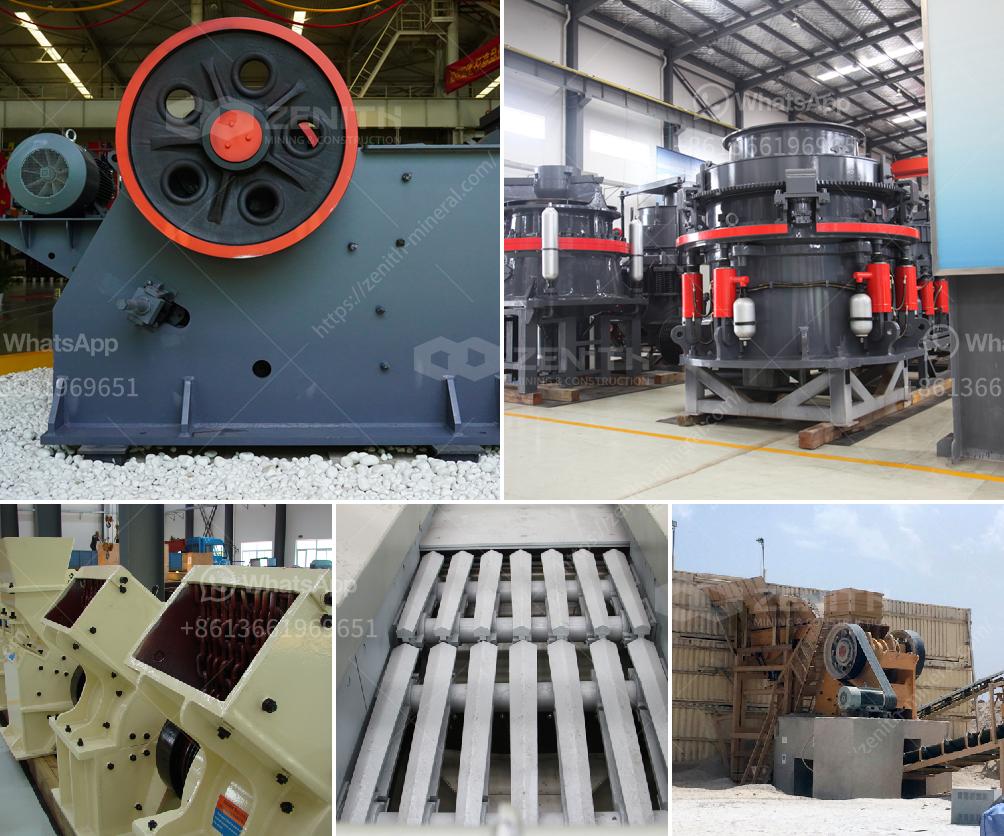

Frame: The frame is the structural component that supports the entire machine. It is usually made of metal to provide stability and durability.

Sieve: The sieve is the core component of the machine. It is a mesh or perforated plate that allows smaller particles to pass through while retaining larger particles. Sieves can have different mesh sizes depending on the required particle size.

Motor: The motor provides the necessary power to vibrate or rotate the sieve. The type of motor used can vary, but it is typically an electric motor.

Vibrating Mechanism: In vibrating sieving machines, a mechanism is used to create vibrations that help in the separation process. This can be achieved using eccentric weights or other vibration-inducing components.

Collection Tray: The collection tray is where the sieved sand is collected. It is positioned below the sieve to gather the fine particles that pass through.

Feeding Mechanism: This component ensures a steady flow of sand onto the sieve. It can be a hopper or a conveyor belt that feeds sand into the machine.

The working principle of a sand sieving machine involves the following steps:

Feeding: Sand is fed into the machine through the feeding mechanism. This can be done manually or using an automated system.

Sieving: The sand passes over the sieve, which is either vibrated or rotated. The vibrations or rotations help to separate the sand particles based on size. Fine particles pass through the sieve, while larger particles are retained.

Collection: The fine sand that passes through the sieve is collected in the collection tray. The larger particles that do not pass through the sieve are either discarded or collected separately for further processing.

Manual Sieving Machine: This type of machine requires manual effort to operate. It is suitable for small-scale operations where the volume of sand to be sieved is not very high.

Semi-Automatic Sieving Machine: These machines use a motor to vibrate the sieve but still require manual feeding and collection of sand. They are more efficient than manual sieving machines.

Fully Automatic Sieving Machine: Fully automatic machines are equipped with automated feeding, sieving, and collection mechanisms. They are suitable for large-scale operations and provide high efficiency and consistency.

A sand sieving machine is an essential tool in various industries where the separation of fine particles from coarse particles is required. Its design and operation can vary depending on the specific needs of the application, but the fundamental principle remains the same: to ensure that the sand used is of the desired size and free from impurities.