For creating fine crushed stone, several types of equipment can be utilized depending on the specific requirements of the project. Here are some commonly used machines:

Jaw Crusher: Often used for the primary crushing phase, it can handle larger stones and break them down into smaller pieces suitable for further processing.

Cone Crusher: This equipment is effective in secondary or tertiary crushing stages, offering a high reduction ratio and the ability to create fine, uniform stone particles.

Impact Crusher: Utilized in both primary and secondary crushing, impact crushers are effective for creating finer, more consistent crushed stone by using high-speed impact.

Vertical Shaft Impactor (VSI): Particularly used for producing high-quality fine aggregates, a VSI crusher processes the stone through a high-speed rotor and anvil system.

Hammer Mill: Known for its high-speed impact and shear, a hammer mill is effective for both fine and coarse crushing, making it popular for various stone processing needs.

Roll Crusher: Comprising two rotating cylinders, roll crushers are effective for producing fine crushed stone by compressing the rock between two rollers.

Ball Mill: Although traditionally used for grinding minerals, ball mills can also be employed to crush stone into fine powders.

Sand Making Machine: These specialized machines break down larger stones into fine particles suitable for use in concrete, asphalt, and other construction applications.

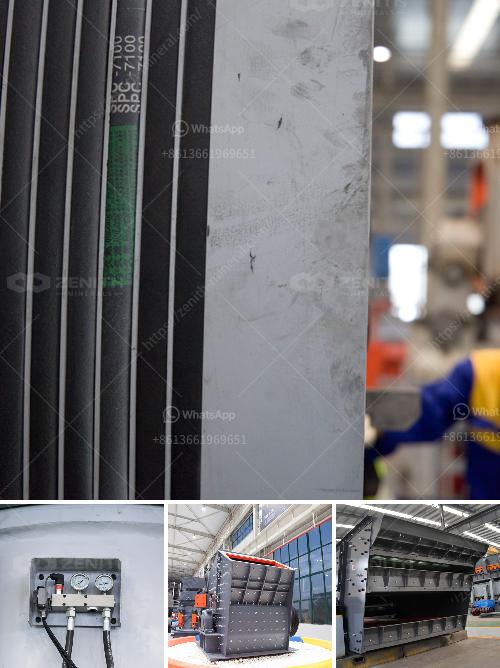

Vibrating Screen: While not a crushing tool per se, vibrating screens are essential for sorting and grading crushed stone, ensuring the final product meets required specifications.

Choosing the right equipment depends on factors such as the type and hardness of the stone, the desired size of the final product, and production capacity requirements.