Operating and maintaining a ball mill efficiently requires adherence to certain protocols and practices. Here's a concise guide to help you perform these tasks effectively:

Operation:

-

Pre-Start Checks:

- Examine the Surroundings: Ensure there are no obstructions around the mill.

- Check Fluid Levels: Verify oil and lubrication levels for moving parts.

- Inspect for Damage: Look for visible wear or damage on mechanical and electrical components.

-

Starting the Mill:

- Load Material: Ensure the material to be ground is loaded into the mill.

- Sequential Start-Up: Start the auxiliary equipment first (e.g., blowers, pumps), followed by the mill itself.

- Adjust Controls: Set the operational parameters such as rotational speed, water-flow rate (if wet milling), and feed rate.

-

Monitoring During Operation:

- Observe Vibration: Consistent vibration may indicate imbalances or other mechanical issues.

- Check Temperature: Excess heat can signal friction problems.

- Listen for Unusual Sounds: Grinding mills should operate smoothly. Unusual noises could indicate worn parts or improper operation.

Maintenance:

-

Regular Inspections:

- Daily: Check lubrication points and oil levels. Inspect and tighten bolts and couplings.

- Weekly: Examine the wear pattern on liners and grinding media.

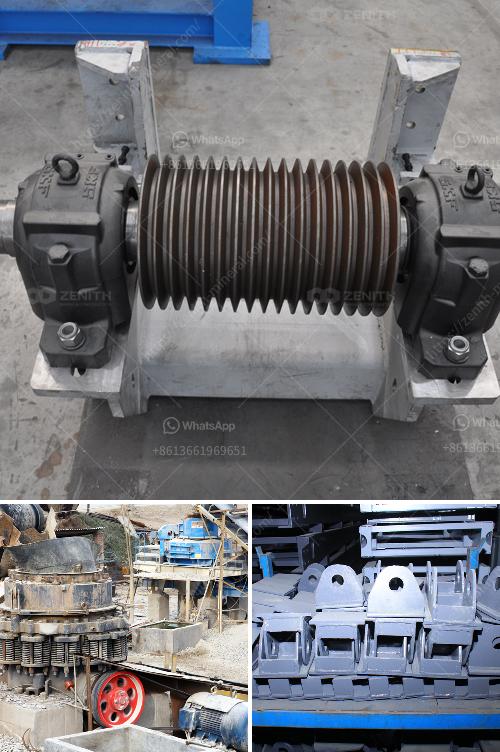

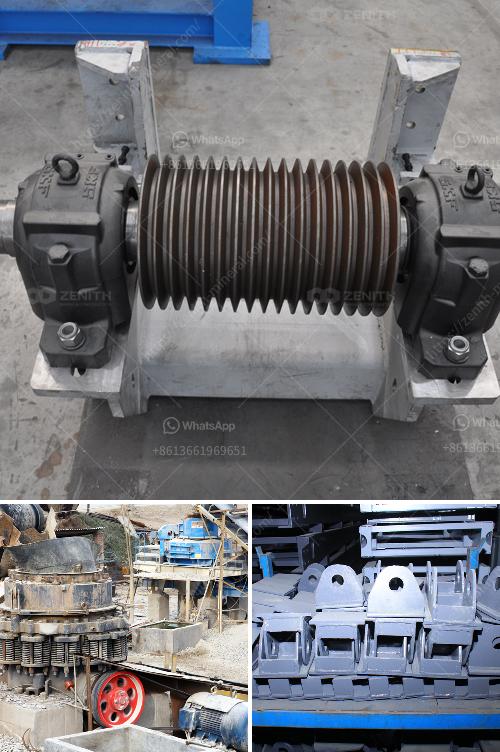

- Monthly: Inspect the driving mechanism, clutch, and gear system for signs of wear or misalignment.

-

Scheduled Servicing:

- Lubrication System: Regularly replace lubricants and check for any leaks.

- Change Liners: Replace liners periodically as they wear down to maintain grinding efficiency and reduce contamination.

- Inspect Bearings: Bearings should be regularly checked and replaced if worn.

-

Preventive Measures:

- Alignment Checks: Ensure all rotating parts stay aligned. Misalignment can cause excessive wear and tear.

- Balance Checking: Imbalance in the mill can lead to inefficient operation and damage.

- Dust Control: Maintain appropriate dust control to ensure the environment is safe and machinery is not contaminated.

-

Record Keeping:

- Maintenance Logs: Keep detailed records of maintenance activities, including dates, parts replaced, and inspections completed.

- Operating Logs: Document operational parameters and monitor them for any deviations that could indicate emerging problems.

Safety:

- Personal Protective Equipment (PPE): Always wear appropriate PPE including hard hats, safety goggles, gloves, and hearing protection.

- Lockout/Tagout Procedures: Ensure the mill is de-energized and locked out during maintenance to prevent accidental startup.

- Emergency Procedures: Train staff on emergency shutdown procedures and ensure emergency stops are accessible and functional.

By maintaining diligence in both the operation and maintenance of your ball mill, you can greatly enhance its efficiency, safety, and lifespan.