Are you looking for information or assistance regarding a 5tph (tons per hour) trial rock stone tin plant? If so, it sounds like you are referring to a processing plant designed to handle and test a capacity of 5 tons per hour for tin ore.

Here are a few key points you might want to consider:

Feed Material: What type of rock or stone is being used, and what is the tin ore content? Understanding the input material is crucial for optimizing the process.

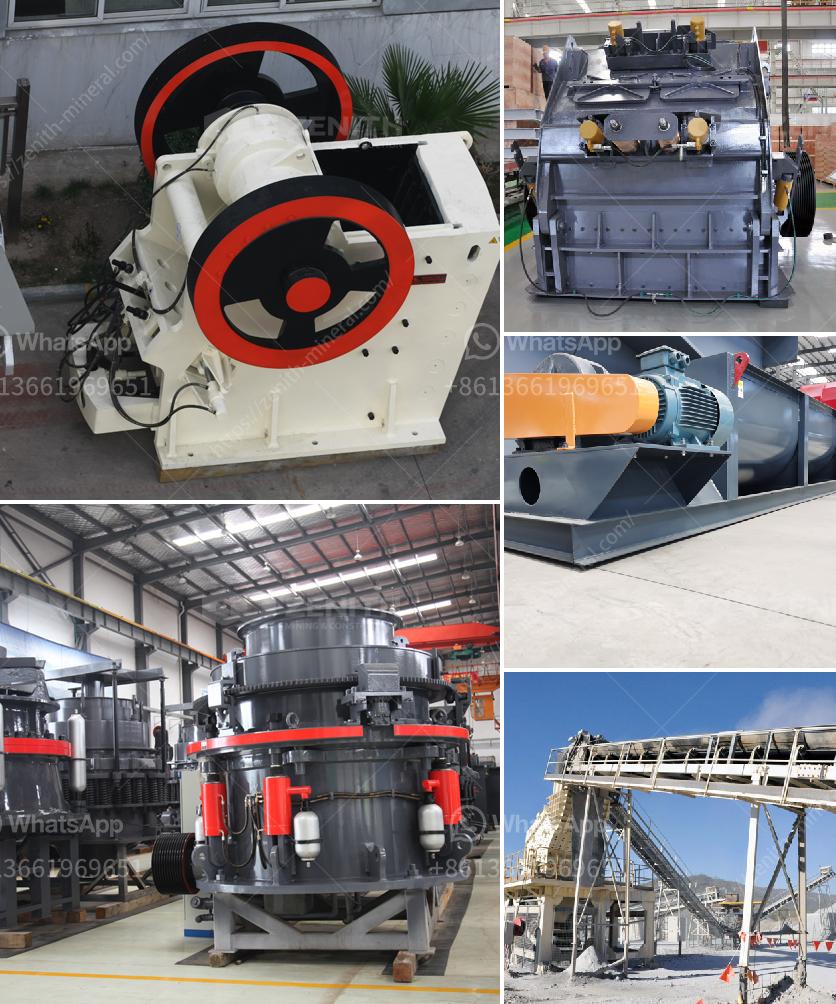

Crushing and Grinding: The plant will likely need machinery for crushing and grinding to reduce the size of the rock and liberate the tin minerals. Equipment such as jaw crushers, cone crushers, and ball mills are commonly used.

Separation and Concentration: Tin ore typically goes through a gravity separation process. Equipment such as shaking tables, spiral chutes, and jigs may be part of the plant operation.

Processing Flowchart: A detailed flowchart outlining each step of the process, from raw material intake to final concentrate, would be essential for efficient operation.

Trial Objectives: Clearly define the objectives of the trial. Are you testing efficiency, recovery rates, equipment durability, or some other factors?

Environmental and Safety Considerations: Ensure that the trial plant complies with local environmental regulations and has appropriate safety measures in place.

Monitoring and Data Collection: Implementing a system for regular monitoring and data collection will help in analyzing the trial results and making necessary adjustments.

Would you like more detailed information on any specific aspect of the plant, or do you have particular questions or requirements for your trial?