A ball mill's internal structure comprises several key components that work together to grind materials into fine powder. Here are the main parts:

Drum (Cylinder): This is the rotating vessel that contains the grinding media and the material to be ground. It's typically made of steel or heavy-duty ceramics.

Liners: These are protective lining materials attached to the inside wall of the drum. They protect the drum from wear and can be made from rubber, steel, or ceramic materials.

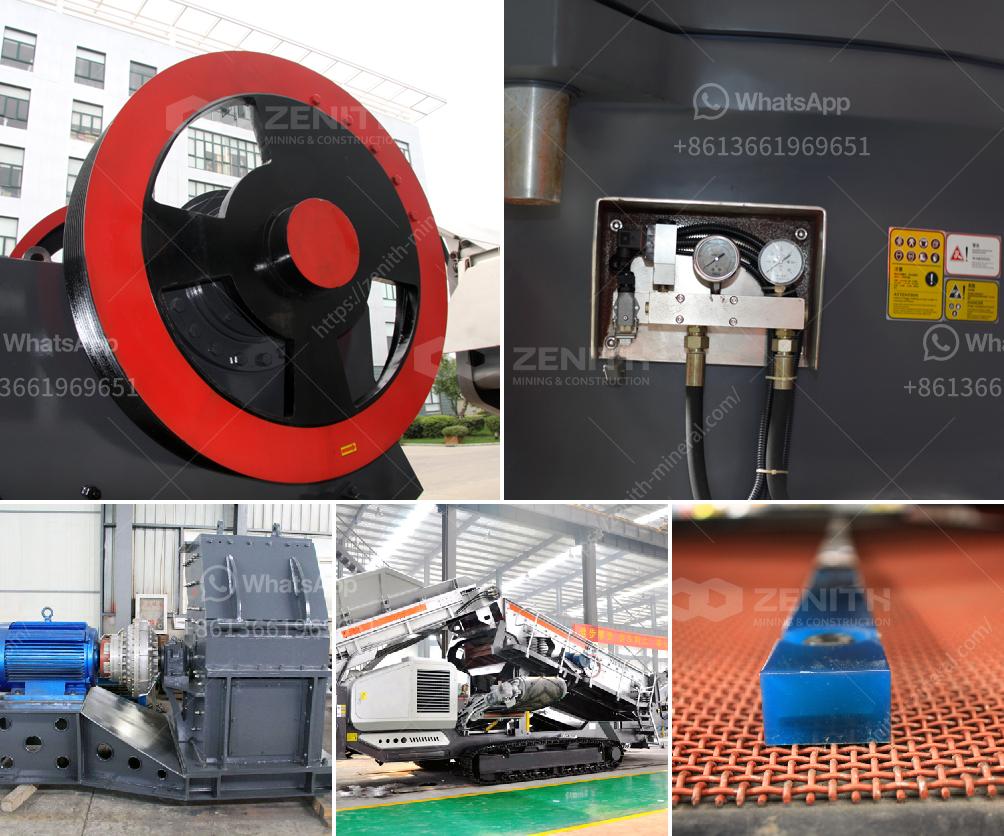

Grinding Media: The balls or rods inside the drum that facilitate grinding. These can be made of steel, ceramic, or other materials.

Trunnions: These are the end supports for the rotating drum, allowing it to spin and conduct the grinding process.

Shell: The outer casing of the drum, which provides structural support and is usually made from forged steel.

Feed End and Discharge End: The areas where materials enter and exit the mill, respectively. They can include hoppers, chutes, and screens.

Internal Bearings: Bearings within the mill support the rotation and align the drum properly.

Rotation System: This typically includes a motor, gearing, and drive shaft that cause the drum to rotate.

Compartments (in some designs): Some ball mills feature multiple compartments to control the size reduction process more efficiently.

Diaphragms: Used in multi-compartment mills, they separate the compartments and help control the flow of material.

These components work in tandem to grind materials effectively in a ball mill.