For sandstone processing, a variety of crushing machinery can be employed depending on the specific requirements and scale of the operation. Here are some commonly used machines:

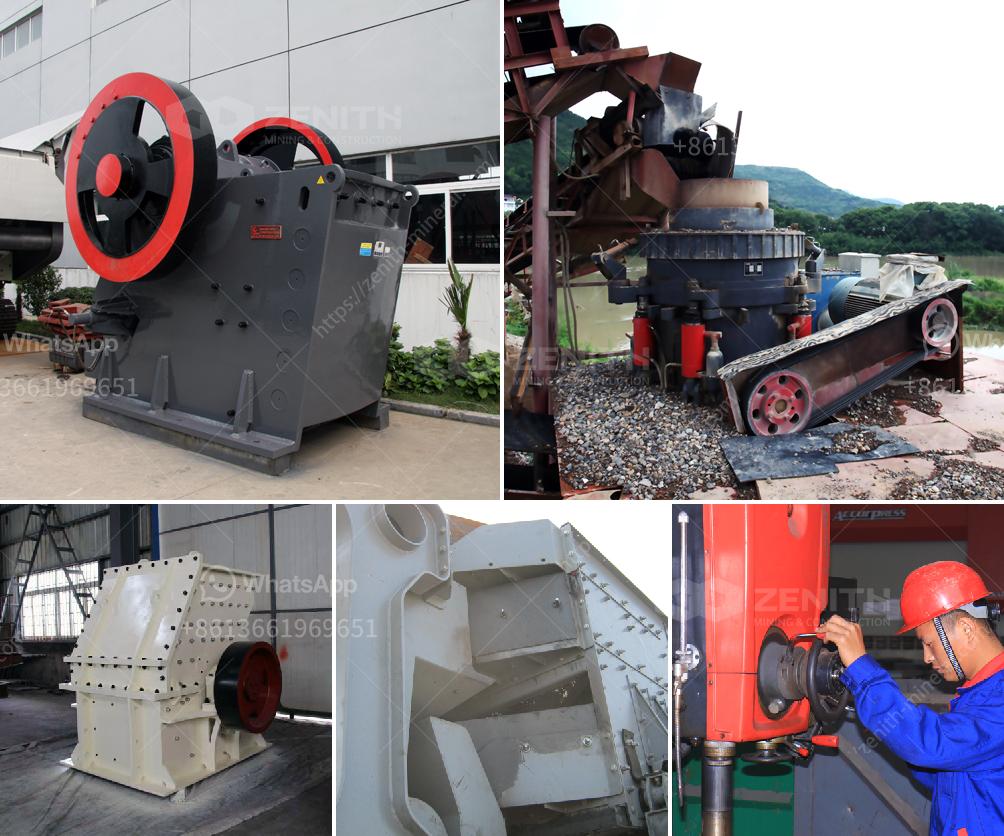

Jaw Crusher: Utilized as a primary crusher, it is effective for initial breaking down of large sandstone rocks into more manageable sizes.

Impact Crusher: Often used for secondary crushing, impact crushers are well-suited for processing medium-hard materials like sandstone due to their high reduction ratios and capacity for producing well-graded product shapes.

Cone Crusher: This type of crusher is ideal for secondary, tertiary, or even quaternary crushing stages. It is especially effective for processing hard and abrasive sandstone to deliver fine and consistent particle sizes.

Sand Maker (VSI Crusher): Vertical shaft impact crushers are used to produce high-quality aquifer sand with precise control over sand particle size and shape.

Hammer Crusher: Effective for intermediate crushing stages, hammer crushers can crush the sandstone into smaller sizes, which is beneficial for various subsequent processes.

Mobile Crushers: These are versatile options providing flexibility and mobility for on-site processing while maintaining high efficiency and convenience.

The selection of the right machinery depends on the size, hardness, and desired final product of the sandstone material, as well as the specific needs and constraints of the operation.